TM 5-3895-346-14

SHOP NOTES

ENGINE OVERHAUL

SHOP NOTES - TROUBLESHOOTING -

SPECIFICATIONS - SERVICE TOOLS

SHOP NOTES

On nonturbocharged engines built prior to serial number 4D-36457, when oil is detected on the -blower rotors or

inside surface of the housing, the blower end plate can be reworked to accommodate a new lip-type oil seal or

a steel insert.

NOTE

Slight phonographic grooves can actually improve sealing. Unless wear is considerable and oil

leakage is evident, the end plate need not be reworked.

Rework Blower End Plate

Use tool kit J 9533 to rework the end plate.

NOTE

On some prior serviced blowers, the end plates may have been reworked to accommodate a

steel insert. In such cases, proceed as follows but omit Step 10.

1.

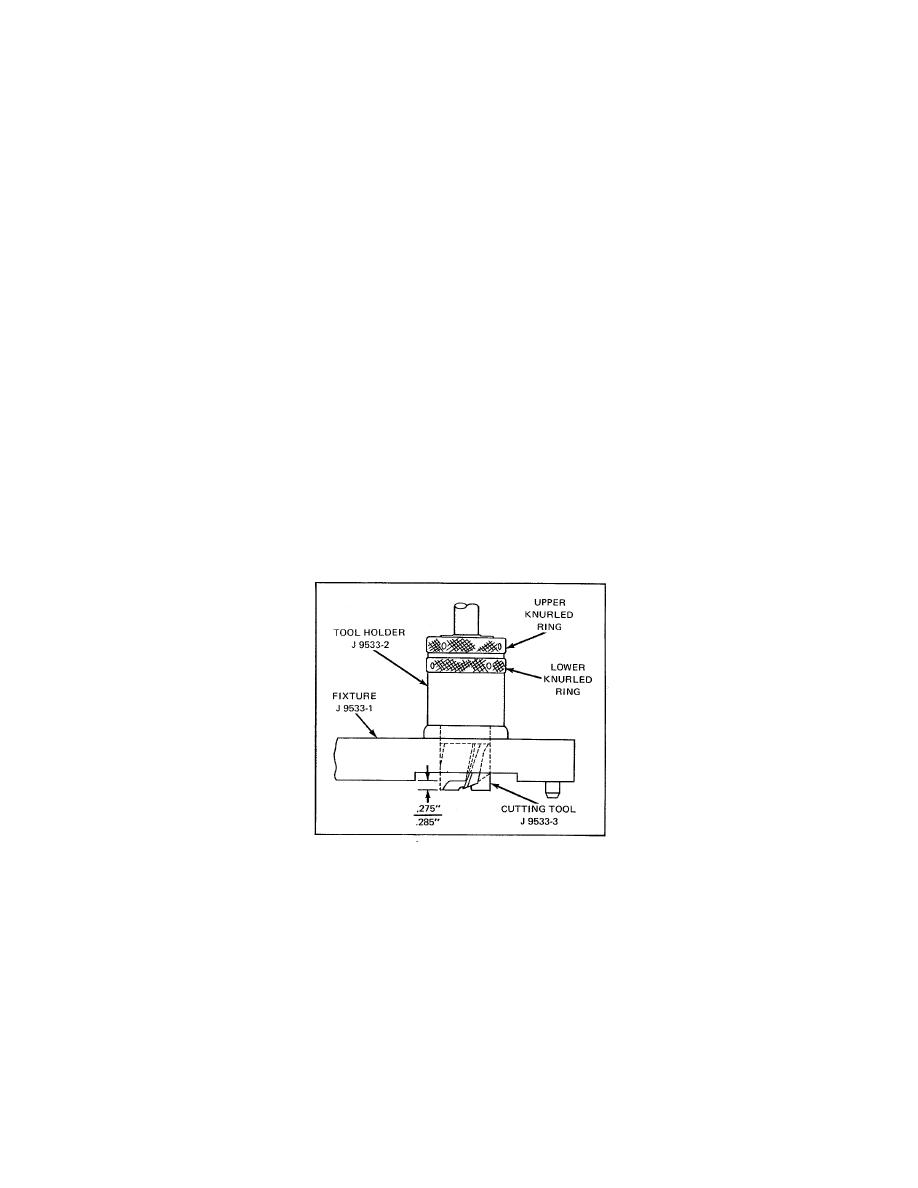

Adjust tool holder J 9533-2 and cutting tool J 9533-3 for the proper counterbore depth as follows:

a.

Insert rough cutting tool J 9533-3 in the tool holder as shown in Fig. 1.

b.

Position the holder and the cutting tool in the fixture J 9533-1.

c.

Loosen the upper knurled ring on the tool holder.

Figure 1. Adjustment of Tool Holder

d.

Rotate the lower knurled ring to raise or lower the cutting tool. Turn the lower knurled ring

until there is a distance of 0.275-0.285 inch between the end of the cutting tool and the bottom of the fixture.

e.

Tighten the upper knurled ring.

2.

Place fixture J 9533-1 on the blower end plate.

3.

Clamp the fixture and the end plate loosely to the bed of a drill press.

4. Install tool holder J 9533-2 in the drill press and insert rough cutting tool J 9533-3 in the holder (Fig.

2).

300