FB 11855-8

1

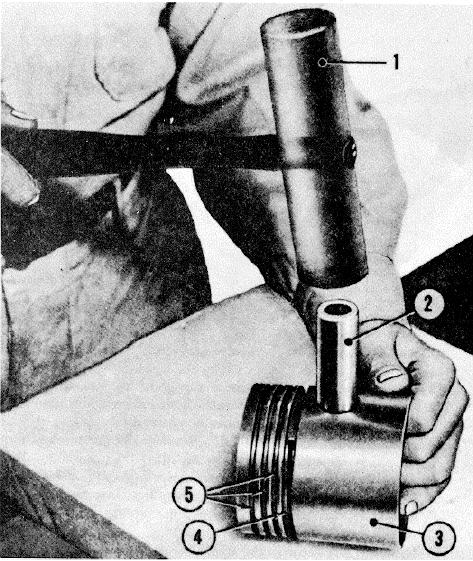

Plastic hammer

4

Oil ring groove 1

2

Piston pin

5

Compression ring grooves

3

Piston

Figure 85. Piston pin fitting.

(5) Invert the piston and hold it with one hand over the cylinder sleeve. Hold the feeler stock and the spring

scale in the other hand.

(6) Place the feeler stock in the cylinder sleeve and lower the piston into position.

(7) Withdraw the feeler stock, observing the spring scale reading.

(8) If clearance is correct, the tension required to withdraw the feeler stock will read 10 to 15 pounds. Too low

or too high readings indicate too much or too little clearance.

212