TM 5-3895-383-24

The axle is used to transmit power from the propel motor to the

rear wheels. Power from the axle propel motor goes through

wheel drive gearbox (4) to the TrueTrac differential (2). The

power from the TrueTrac differential goes through the left and

right planetary gears to the axle shafts. The axle shafts have

flanges (5) in order to mount the wheels. The wheels transfer

the power to the ground.

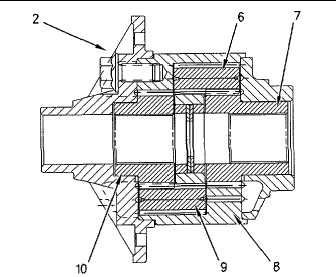

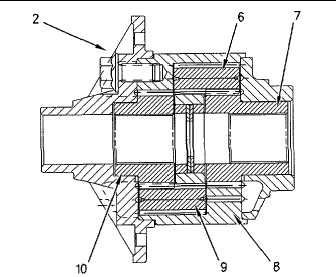

Illustration 60

TrueTrac Differential

(2) TrueTrac differential. (6) Pinion. (7) Side gear. (8) Case.

(9) Pinion. (10) Side gear.

The TrueTrac differential is a gear type limited slip differential.

The following features are the two main functions of the

TrueTrac differential.

1.

The TrueTrac differential limits the wheel spin and the

power loss when one wheel loses traction.

2.

The TrueTrac differential allows differences in wheel

speed when the machine is in a turn or on an uneven

surface.

When the machine is operated in a straight direction and over

a smooth surface, the TrueTrac differential operates as a

standard differential. Equal force is applied to each side gear

(7) and (10). Essentially, the TrueTrac differential equally

divides the power between the rear wheels.

The TrueTrac differential automatically engages when the

compactor makes a turn, or when one of the wheels loses

traction. One of the pinions (6) or (9) separates from the side

gear (7) or (10). This causes the pinion to wedge into the

pockets in the case (8). In this case, the TrueTrac differential

proportionally distributes the torque to each wheel so that the

wheel with the poorest traction will be controlled. The majority

of the torque is transferred to the wheel with the most solid

footing.

NOTE:

The TrueTrac differential will not engage when

one of the wheels is off the ground. A small

amount of resistance must be applied to this

wheel in order for the TrueTrac differential to

property engage.

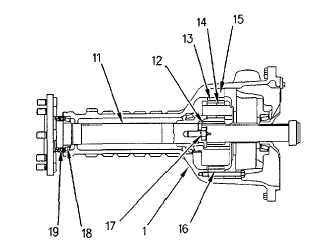

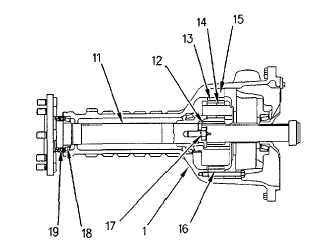

Illustration 61

Left Axle Housing Assembly

(1) Left axle housing assembly. (11) Axle shaft. (12) Sun

gear. (13) Planetary gears. (14) Needle bearings. (15) Ring

gear housing. (16) Planetary ring gear. (17) Axle shaft

retaining bolt. (18) Axle bearing. (19) Seal.

The planetary ring gears (16) are pressed into ring gear

housings (15). The planetary gears are positioned around the

sun gear (12) and within the planetary ring gear (16).

Planetary gears (13) are mounted to the carrier by shafts and

the planetary gears rotate on needle bearings (14). Each

carrier is located inside the planetary ring gears (16). The

carriers will rotate at a slower speed than the sun gears. The

carriers are connected to axle shaft (11) with internal splines.

Axle shaft (11) is mounted in a tapered roller bearing and the

end play is adjusted via a shim under axle shaft retaining bolt

(17).

10-53