TM 5-3895-383-24

Disassemble & Assemble Water

Pump 1361-017

Tools Needed

A

B

C

1P-0510

Dive Group

1

1P-0520

Driver Group

1

5P-9722

Seal Driver

1

Start By:

a.

remove water pump

Fluid Spillage Containment

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting and

repair of the machine. Be prepared to collect the fluid with

suitable containers before opening any compartment or

disassembling any component containing fluids. Refer to

"Tools And Shop Products Guide", NENG2500 for tools and

supplies suitable to collect and contain fluids in Caterpillar

machines. Dispose of fluids according to local regulations and

mandates.

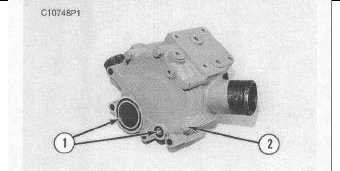

1.

Remove two O-ring seals (1) from the rear cover of the

water pump. Remove four bolts (2) and the washers.

Remove the rear cover and gasket.

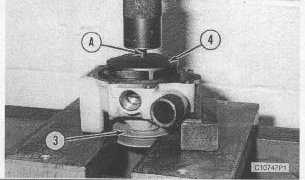

2.

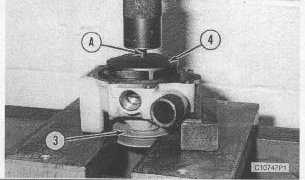

Put the water pump in a press. Use spacer plates to

level the water pump as shown.

3.

Using a suitable size drive plate from Tool (A) and a

press, push the shaft and pulley (3), as a unit, out of

impeller (4). Remove the impeller.

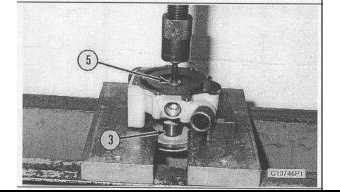

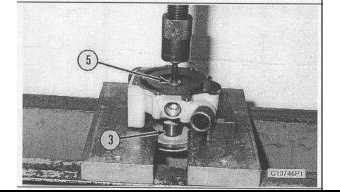

NOTICE

Do not allow the shaft and pulley to fall to the floor as it is

being removed from seal (5) and the water pump housing.

Damage to the shaft and pulley will result.

4.

Continue to push the shaft and pulley out of seal (5) and

the water pump housing.

8-5