TM 5-3895-383-24

Table 9

Air Conditioning Fittings

O-Ring Fitting End

45 Degree Flare

Fitting End

Thread

Size

Inch

Standard

Torque

Steel

Tubes

Standard

Torque

Aluminum

Tubes

Standard

Torque

5/8 - 18

14 4 Nm

(10 3 lb-ft)

30 3 Nm

(22 2 lb-ft)

23 3 Nm

(17 2 lb-ft)

3/4 - 16

27 4 Nm

(20 3 lb-ft)

52 5 Nm

(38 4 lb-ft)

33 4 Nm

(24 4 lb-ft)

7/8 - 14

40 4 Nm

(30 3 lb-ft)

60 7 Nm

(44 5 lb-ft)

38 4 Nm

(28 3 lb-ft)

1 1/16 - 14

45 5 Nm

(33 4 lb-ft)

75 8 Nm

(55 6 lb-ft)

50 5 Nm

(37 4 lb-ft)

Tapered Pipe Thread Fittings

SMCS Code: 7553

Table 10

Tapered Pipe for Thread Fittings

Standard Torque

Thread Size

Of the Pipe

Inch

Threads with

5p - 3413

Pipe Sealant

Threads without

Pipe Sealant

1/16 - 27

10 Nm (7 lb-ft)

10 Nm (7 lb-ft)

1/ - 27

16 Nm (12 lb-ft)

16 Nm (12 lb-ft)

1/4 - 18

20 Nm (15 lb-ft)

25 Nm (18 lb-ft)

3/8 - 18

35 Nm (26 lb-ft)

45 Nm (3 lb-ft)

1/2 - 14

45 Nm (33 lb-ft)

60 Nm (4 lb-ft)

3/4 - 14

60 Nm (4 lb-ft)

75 Nm (55 lb-ft)

1 - 11 12

75 Nm (55 lb-ft)

90 Nm (65 lb-ft)

1 1/4 - 11 1/2

90 Nm (65 lb-ft)

110 N m (80 lb-ft)

11 - 11 1/2

110 N m (80 lb-ft)

130 N m (95 lb-ft)

2 - 11 1/2

130 N m (95 lb-ft)

160 N m (120 lb-ft)

NOTE:

Use 50 percent of the torque values from Table 10

when the fitting, the plug or the port material is

nonferrous.

Tightening Other Fittings

SMCS Code: 7553

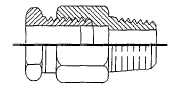

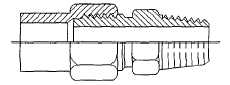

Hi Duty Tube Fittings (Shear Sleeve)

Illustration 7

After the tube has been put through the nut and after the tube

makes contact against the tube shoulder in the fitting body,

turn the nut with a wrench until a small decrease in torque Is

felt. The small decrease in torque indicates that the sleeve has

been broken off of the nut. Hold the tube in order to prevent

the tube from turning. Tighten the nut for an additional 1-1/2

turns.

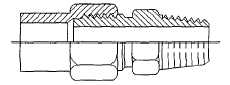

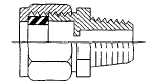

Hi Seal Fittings

Illustration 8

Put the nut and the sleeve over the tubing so that the end of

the sleeve that is short and heavy is facing the end of the

tubing. Put the tube end against the counterbore in the body of

the fitting and tighten the nut until the nut is over the last thread

on the body. The remainder of the space is used whenever

the fitting is removed and installed again.

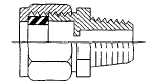

Tube Fittings that are Not Flared

Illustration 9

4-9