TM 5-3895-382-24

Propel Motor Case Leakage Test

Drum Propel Motor

Refer

to

the

WARNING

on

the

first

page

of

Troubleshooting.

Tools Needed

4C-6500

Temperature Probe

1

4C-8689

Flow Meter

1

NOTE:

Install 4C6500 temperature

probe

into

the

hydraulic tank. Operate the machine until the oil

temperature reaches 38°C (100° F).

1.

Stop the machine. Apply the parking brake.

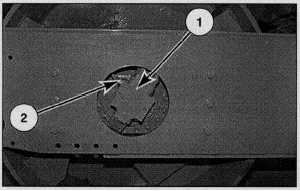

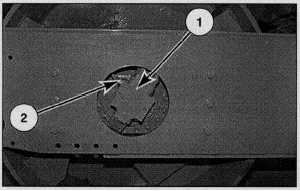

Drum Propel Motor

(1) Drum propel motor. (2) Oil drain line.

2.

Disconnect oil drain line (2) from drum propel motor (1).

3.

Connect a short length of hose to the fitting that line (2)

was connected to. Connect the other end of the hose to

the inlet of the flow meter. Connect the drain line to the

outlet end of the flow meter.

4.

Start and run the machine at low idle for several minutes

then run at high idle until the hydraulic oil temperature

reaches 38C (100F) again. Engine rpm should be

2350 ± 50 rpm.

5.

With the machine stationary read the amount of oil

going through the flow meter. If there is more than 4

liter/min (1 U.S. gpm) of leakage, the motor has too

much internal leakage and must be repaired or

replaced. While moving the flushing valve sends 2 gpm

of additional oil.

6.

Remove all test tooling and connect the oil line back to

the motor.

Axle Propel Motor

Refer

to

the

WARNING

on

the

first

page

of

Troubleshooting.

Tools Needed

4C-6500

Temperature Probe

1

4C-8689

Flow Meter

1

NOTE:

Install

4C6500

temperature

probe

into

the

hydraulic tank. Operate the machine until the oil

temperature reaches 38°C (100°F).

1.

Stop the machine. Apply the parking brake.

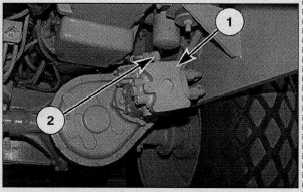

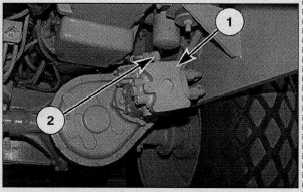

Axle Propel Motor

(1) Axle propel motor. (2) Oil drain line.

2.

Disconnect oil drain line (2) from axle propel motor (1).

3.

Connect a short length of hose to the fitting that line (2)

was connected to. Connect the other end of the hose to

the inlet of the flow meter. Connect the drain line to the

outlet end of the flow meter.

11-49