TM 5-3895-382-24

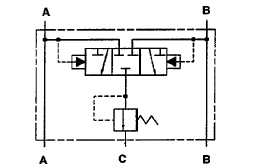

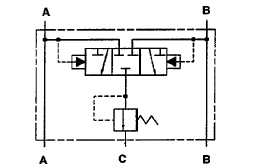

Motor Flush Valve

Motor Flush Valve.

(A) Closed loop circuit port. (B) Closed loop circuit port.

(C) Flush port.

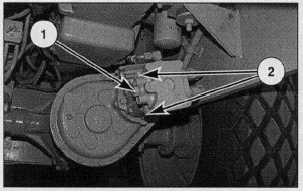

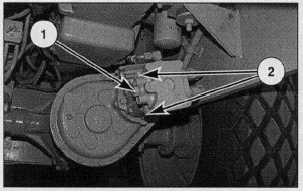

Axle Propel Motor.

(1) Relief valve. (2) Crossover shuttle check valve.

The motor flush valve is located in the axle motor of the propel

closed loop circuit. Lines (A) -(A) and (B) -(B) represent both

sides of the closed loop circuit. The direction of tilt of the pump

swashplate, either FORWARD or REVERSE operation,

determines direction of flow in the loop. Direction of flow in the

loop determines whether a line is high pressure or low

pressure.

Pilot pressure on the high pressure side shifts spring centered

crossover shuttle check valve (2). The low pressure side

opens to relief valve (1). The relief valve is set at 1724 kPa

(200 psi). The charge relief valve in the flushing vale is set at

1724 kPa (200 psi). Because the relief valve is set at a lower

pressure, charge pressure oil crosses the relief valve. Oil

flows through flush port (C) to the motor case. This oil cools

and flushes the motor and pump.

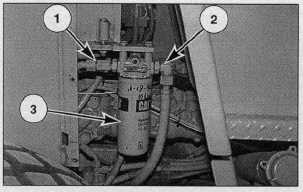

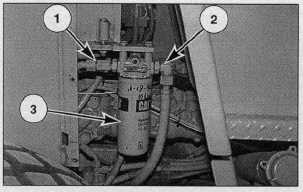

Charge Filter

Charge Filter.

(1) Inlet port. (2) Outlet port. (3) Element.

Before being used in the two propel loops, charge oil passes

through the charge filter. During normal operation, charge oil

comes from the steering pump, enters the filter at inlet port (1),

and passes through the element (3). The element traps any

debris that is in the oil. Oil then exits the filter through outlet

port (2), and is routed to the propel pumps.

If the element becomes clogged with debris, the restriction to

the flow of oil causes a pressure increase outside the element.

If the pressure differential across the element reaches 350 kPa

(50 psi), the pressure of the oil causes the bypass valve to

shift. Charge oil passes directly through the bypass valve and

exits the filter through the outlet port to the thermal bypass

valve.

The filter has a manual indicator to show the oil is taking the

bypass route and an audible alarm sounds at 1205 kPa (175

psi) for low charge pressure.

Correct maintenance must be used to make sure that the filter

element does not become clogged, stopping the flow of clean

oil to the propel system.

11-16