TM 5-3895-382-24

Drum Propel.

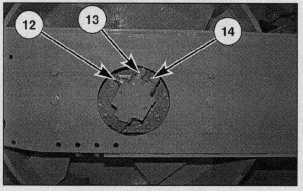

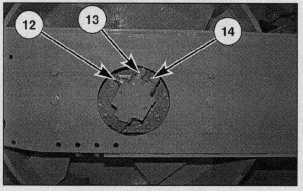

(11) Brake line. (12) Case drain outlet. (13) Closed circuit loop line.

(14) Closed circuit loop line.

High pressure oil enters the motor through closed circuit loop

line (13). Oil flows through port plate (1) to piston (2) in

cylinder block (5). The force of the oil pushes the piston

against swashplate (8). The piston reacts by trying to reach

maximum outward stroke. Since the swashplate is at an angle,

the piston starts to move along the swashplate. This

movement causes the cylinder and output shaft (4) to rotate.

As the cylinder and output shaft continue to rotate, the piston

moves around the angled swashplate and piston stroke starts

to decrease. Oil is forced through the opposite side of port

plate (1) to low pressure closed circuit loop line (14).

NOTE:

Closed circuit loop line (14) is called a low

pressure loop line, and dosed circuit loop line (13)

is called a high pressure loop line in this example.

Moving the pump swashplate overcenter in the

opposite direction causes a change in the

direction of flow in the pump and motor closed

circuit loop (FORWARD or REVERSE operation).

Closed circuit loop line (14) becomes high

pressure and closed circuit loop line (13)

becomes low pressure. A change in the direction

of flow in the closed loop circuit causes a change

in motor direction of rotation.

Charge pressure on the low pressure side of the closed circuit

loop is routed through the motor flush valve to the motor case.

Oil from the motor flush valve enters the motor case through

case drain outlet (12). Oil circulated through the motor case

serves to cool and flush the motor.

Drum Motor Servo Control.

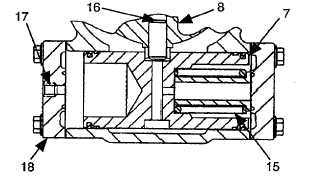

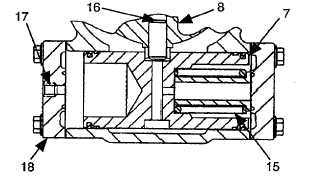

(7) Servo piston assembly. (8) Swashplate. (15) Spring. (16) Pin.

(17) Servo pressure port. (18) End cap.

The motor uses servo piston assembly (7) to change the

operating angle of swashplate (8). The assembly is controlled

by the pump charge pressure through the speed shift control

valve. The speed shift switch is located on the main console.

The piston is connected to the swashplate by pin (16). Servo

pressure port (17) is located in end cap (18). When the speed

shift switch is in the HIGH position, the control valve opens.

Change oil pressure at the servo pressure port acts on the

piston and overcomes the force of spring (15). The piston

moves and causes the swashplate to rotate. In this position

the swashplate is at the minimum angle. At minimum angle,

the motor pistons have minimum stroke (displacement) and

can produce high speeds.

When the switch is in the LOW position, the control valve

closes and oil pressure to the servo pressure port is open to

tank. Spring (15) pushes piston servo assembly (7) and

causes swashplate (8) to rotate. The spring holds the piston

and swashplate at the maximum angle. At maximum angle,

the motor pistons have maximum stroke (displacement) and

can produce low speeds.

11-12