TM 5-3895-382-24

The cold starting aid is connected by a shaft to the advance

lever for the timing of the fuel injection pump. The cold starting

aid and the advance lever are internal components of the

Lucas DP200 Series fuel injection pump.

Fuel Injection Pump (Stanadyne) On Type 2 Engines

and 7BJ

NOTE:

For a complete description of Type 1 and Type 2

engines, refer to the Systems Operation, Testing

and Adjusting Module, "Engine Design" for more

information.

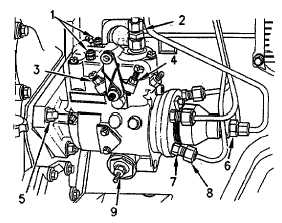

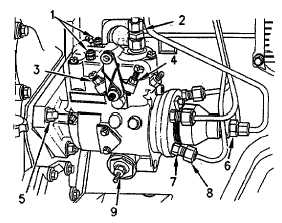

Illustration 15

Components of the fuel injection pump (Stanadyne)

Table 10

(1) Electrical connection for stop

(6) Nut for end cap

solenoid

(7) Fitting for fuel discharge

(2) Connection for the fuel return

(8) Fuel line connection to

(3) Adjustment screw for low idle

fuel injection nozzles

(4) Adjustment screw for high idle

(9) Screw for adjustment

(5) Range nut

timing advance

The Stanadyne fuel injection pump on Type 2 engines is not a

serviceable part. The adjustment for the timing of the fuel

injection pump is made internally. The adjustment is tamper

proof. The low idle is adjustable. The adjustment for high idle

is preset at the factory. High idle should only be adjusted by

personnel with the correct training. The pump has a boost

control and an engine stop solenoid. The design of the pump

will automatically remove air from the pump.

The fuel injection pump has an electrically operated cold

starting aid which holds the timing of the pump in an advanced

position when the engine is cold. The advance lever of the

pump is enclosed within the pump housing. The cold starting

aid should only be adjusted by personnel with the correct

training.

The cold starling aid is connected by a shaft to the advance

lever for the timing of the fuel injection pump. The cold starling

aid and the advance lever are internal components of the

Stanadyne fuel injection pump.

A temperature switch is installed in the coolant passage which

is located at the rear of the timing case. The temperature

switch sends current to the electrical connection of the cold

starling aid (not shown) when the engine is started and when

the engine is below normal operating temperature. The body

contains a wire coil with high electrical resistance. The wire

coil surrounds an element which is filled with wax. The wire

coil heats the wax which then expands. The expansion of the

wax forces a rod to move the lever of the timing advance. The

lever continuously adjusts the pump to the correct timing for

the normal operating temperature.

6-17