TM 5-3895-382-24

The transfer pump (9) is located at the rear of distributor rotor

(16) in the end cap. The end cap also contains the strainer for

the fuel inlet and the pressure regulator (10) for the transfer

pump. The transfer pump has a positive displacement vane.

The pressure that is generated by the transfer pump is

automatically compensated for the effects of viscosity due to

temperature changes and fuel grades. The distributor rotor

(16) has a single axial bore with the following passages:

Two charging ports

One discharge port

The single discharge port serves all of the head outlets to the

fuel injection lines. The hydraulic head (14) contains the

following components:

The bore for the rotor

The bore for the metering valve (7)

The charging ports

The discharge fittings (8) of the head

The high pressure fuel lines to the fuel injection nozzles are

fastened to these discharge fittings (8). The fuel injection

pump contains a mechanical governor (4). The centrifugal

force of the governor flyweights (3) that are in the retainer is

transferred in order through the following items: a sleeve to the

governor arm, linkage, and metering valve (7). The timing

advance (12) is a hydraulic mechanism. The timing advance

unit performs one of the following functions:

Advance the delivery of fuel

Retard the delivery of fuel

An electrical stop solenoid is contained inside the governor

housing. The electrical ground is on top of the governor

housing. The supply connections are on the top of the

governor housing. When the voltage is applied, the plunger of

the solenoid moves in order to block the flow of fuel to the

engine. When the fuel flow is stopped, the engine stops.

Fuel Injection Pump (Lucas DP200 Series) On Type 2

Engines and 7BJ

NOTE:

For a complete description of Type 1 and Type 2

engines, refer to the Systems Operation, Testing

and Adjusting Module, "Engine Design" for more

information.

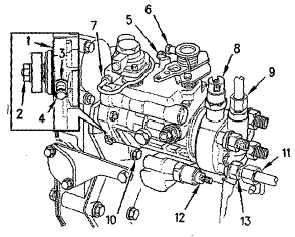

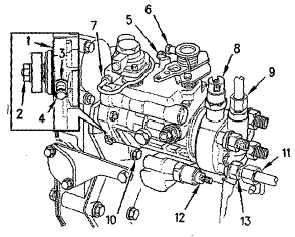

Illustration 14

Components of the fuel injection pump (Lucas DP200 Series)

Table 9

(1) O-ring

(8)

Electrical connection for

(2) Hub nut

stop solenoid

(3) Locking spacer

(9)

Fuel supply connection

(4) Locking screw

(10) Mounting flange

(5) Low idle adjustment screw (11) The fuel discharge lines

(6) High idle adjustment

that supply fuel to the

screw

fuel injector nozzles.

(7) Connection for the fuel

(12) Screw for adjustment of

return

timing advance

(13) Fittings for fuel discharge

The Lucas DP200 Series fuel injection pump is not a

serviceable part. The internal adjustment for the pump timing

is tamper proof. The adjustment for high idle is preset at the

factory. High idle should only be adjusted by personnel with

the correct training. The low idle is adjustable. The fuel

injection pump has a boost control and an engine stop

solenoid. The pump also has a self-vent feature which

removes air from the pump.

The fuel injection pump has a cold starting aid. The cold

starting aid advances the timing of the pump when the engine

is cold. The cold starting aid is electrically operated. The cold

starting aid should only be adjusted by personnel with the

correct training.

6-16