TM 5-3895-382-10

Operation Section

4-32

Operating Techniques

Operating Techniques

Operating Technique Information

Operate the engine at full rpm for maximum

braking, steering and propel control response.

Operation below full throttle will adversely affect

response.

When climbing steep grades, the propel control

lever must be moved SLOWLY to avoid engine

stall and possible loss of machine control.

NOTICE

Do not apply the parking brake while the machine

is moving unless an emergency exists. Use of the

parking brake as a service brake in regular

operation will cause severe damage to the brake

system.

Attain desired travel speed before engaging the

vibratory system.

Avoid using the leveling blade (if equipped) as plow or

digging device. Machine damage may occur.

NOTICE

Do not operate the vibratory system without

machine movement. The lubrication system for the

vibratory system works only while the drum is

turning. Shortened bearing life will result.

Shut the vibratory system off when passing over

concrete or hard pavement.

Begin the first compaction pass along the side of the

work with subsequent passes gradually working

towards the center. Overlap the previous pass by

approximately 200 mm (7.75 in) to eliminate

uncompacted strips.

NOTICE

Before changing the vibratory amplitude selection,

the system should be completely stopped.

Vibratory Operation - High Amplitude

Placing the vibratory system in high amplitude

increases the total dynamic force and height of drum

movement on each vibration cycle.

High amplitude is used whenever:

The job site requires higher compaction forces to

meet density requirements.

The lift or depth of material to be compacted is 254

mm (10.0 in) or more.

NOTE: High amplitude can cause material to break

down if passes continue to be made once the

specified density has been achieved.

NOTE: Every job site is different due to soil conditions,

such as moisture content and material. To

determine the amplitude and the number of

passes required, establish a test plot at each

job site.

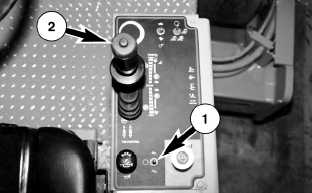

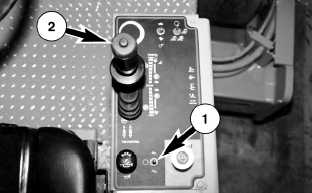

1. Place vibratory system in high amplitude by moving

vibratory control switch (1) backward.

2. Start the vibratory system by pressing vibration

on/off switch (2) on top of the propel control lever.

3. Stop the vibratory system by pressing vibration

on/off switch (2).

NOTE: Moving vibratory control switch (1) to the off

position will also stop the vibratory system.

NOTE: If decoupling (separation of the drum from the

material being compacted) occurs, select low

amplitude.