DETROIT DIESEL 53

1.7.4

IDLER GEAR AND BEARING ASSEMBLY

IN-LINE

ENGINES

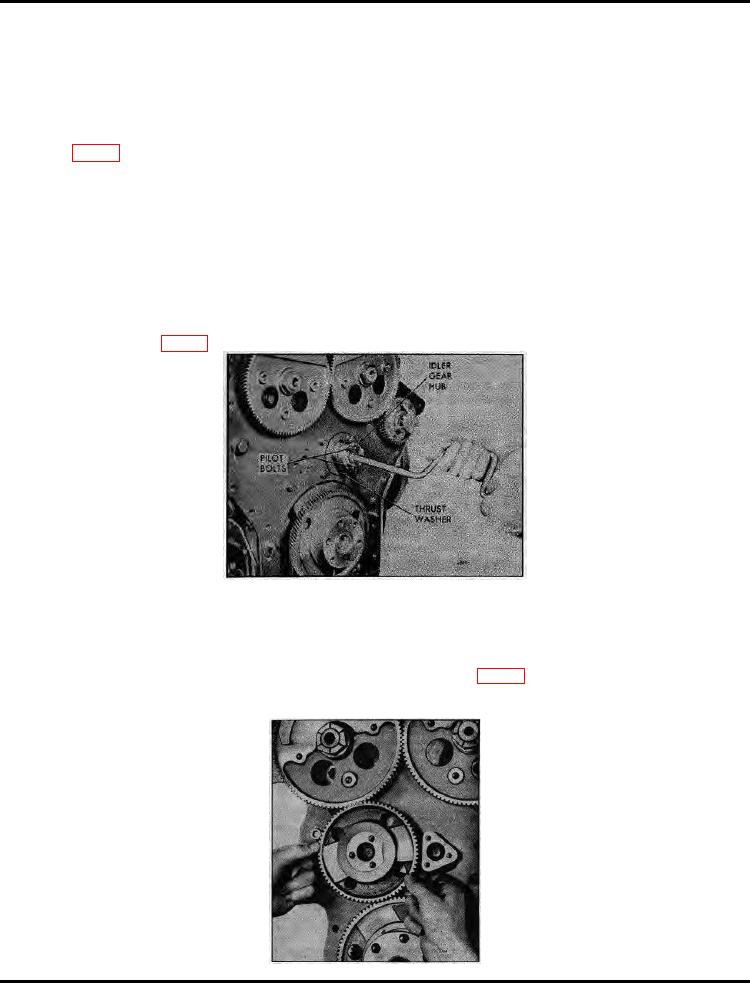

The engine idler gear and bearing assembly, located at the flywheel end of the engine, meshes with the

camshaft and crankshaft gears and rotates on a stationary hub. The hub is secured directly to the cylinder

block by a bolt which passes through the hub and three bolts which pass through the flywheel housing, hub and

end plate (Fig. 1).

Two timing marks (a triangle within a circle) are stamped on the idler gear diametrically opposite (180) to one

another.

The inside diameter of the idler gear bearing is 2.186 "-2.187 " and the outside diameter of the idler gear hub is

2.1825 "-2.1835 ". Therefore, the clearance between the idler gear hub and the idler gear bearing is .0025 " to

.0045 ", with a maximum allowable wear limit of .007 ".

A thrust washer is provided on both sides of the idler gear and bearing assembly. The standard thickness of

the idler gear and bearing assembly is 1.233 " to 1.234 " and the standard thickness of the two thrust washers is

.236 " to .240 "; thus, the clearance between the thrust washers and the idler gear is .006 " to .013 ", with a

maximum allowable wear limit of .017 "

On an In-line engine, the idler gear is positioned on the left-hand side for a right-hand rotating engine as viewed

from the rear. Refer to Fig. 5 under General Description.

Figure 1. Installing Idler Gear Hub

On early engines, an idler gear spacer (dummy hub) was used on the side opposite the idler gear. Currently

the flywheel housing has an integral cast hub and a .015 " thick shim is used between the flywheel housing and

the end plate.

Remove Idler Gear and Bearing Assembly (Flywheel Housing Removed)

1. Remove the idler gear outer thrust washer from the idler gear hub (Fig. 3).

2. Slide the idler gear straight back off of the idler gear hub.

3. Remove the bolt which secures the idler gear hub to

Figure 2. Installing Idler Gear

August, 1972 SEC. 1.7.4 Page 1