DETROIT DIESEL 53

1.6.2

CONNECTING ROD BEARINGS

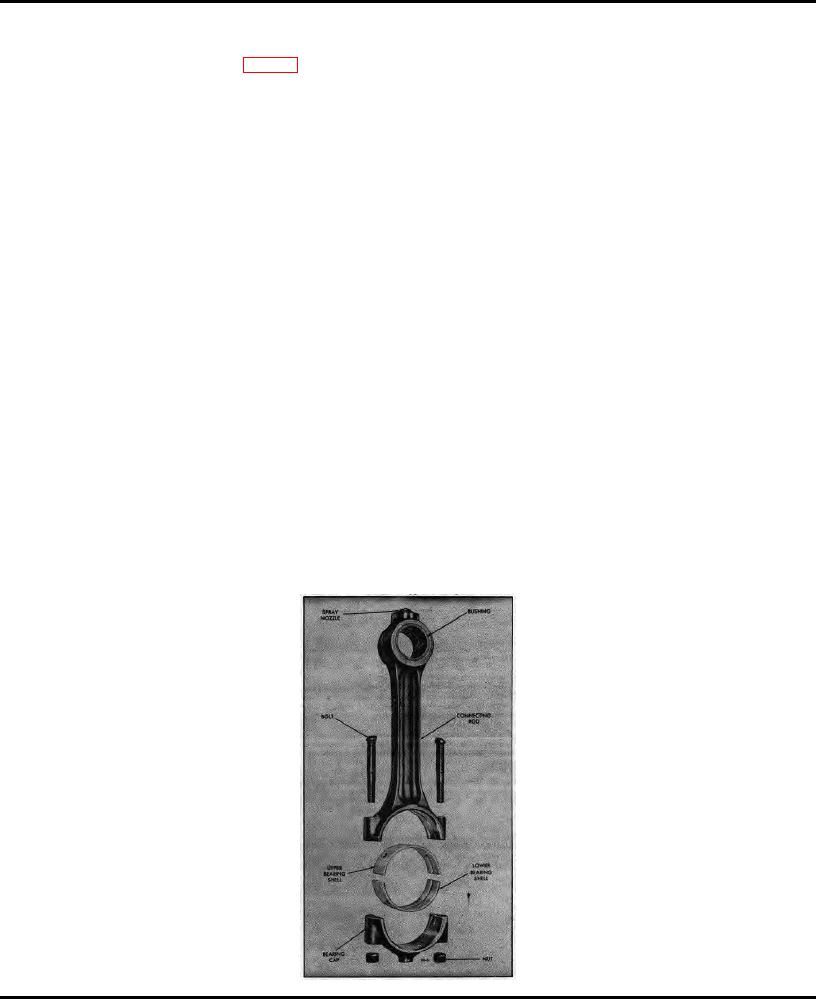

The connecting rod bearing shells (Fig. 1) are precision made and are replaceable without shim adjustments. They

consist of an upper bearing shell seated in the connecting rod and a lower bearing shell seated in the connecting rod cap.

The bearing shells are prevented from endwise or radial movement by a tang at the parting line at one end of each

'bearing shell.

The upper and lower connecting rod bearing shells are different and are not interchangeable. The upper bearing shell

has two short oil grooves and two oil holes; each groove begins at the end of the bearing shell and terminates at an oil

hole. The lower bearing shell has a continuous oil groove from one end of the shell to the other. These grooves

maintain a continuous registry with the oil hole in the crankshaft connecting rod journal, thereby providing a constant

supply of lubricating oil to the connecting rod bearings, piston pin bushings and spray nozzle through the oil passage in

the connecting rod.

Remove Bearing Shells

The connecting rod bearing caps are numbered 1, 2, 3, etc. on an In-line engine with matching numbers stamped on the

connecting rods. When removed, each bearing cap and the bearing shells must always be reinstalled on the original

connecting rod.

Remove the connecting rod bearings as follows:

1. Drain the oil and remove the oil pan.

2. Remove the oil inlet pipe and screen assembly.

3. Remove one connecting rod bearing cap. Push the connecting rod and piston assembly up into the cylinder liner far

enough to permit removal of the upper bearing shell. Do not pound on the edge of the bearing shell with a sharp tool.

4. Inspect the upper and lower bearing shells as outlined under Inspection.

5. Install the bearing shells and bearing cap before another connecting rod bearing cap is removed.

Inspection

Bearing failures may result from deterioration (acid formation) or contamination of the oil or loss of oil. An analysis of the

lubricating oil may be required to determine if corrosive acid and sulphur are present which cause acid etching, flaking

and pitting. Bearing seizure may be due to low oil or no oil.

After removal, clean the bearings and inspect them for scoring, pitting, flaking, etching or signs of overheating. If any of

these defects are present, the bearings must be discarded. The upper bearing shells, which

Fig. 1 Connecting Rod and Bearing Shells

April, 1974 Sec. 1.6.2 Page 1