DETROIT DIESEL 53

Valve Operating Mechanism 1.2.1

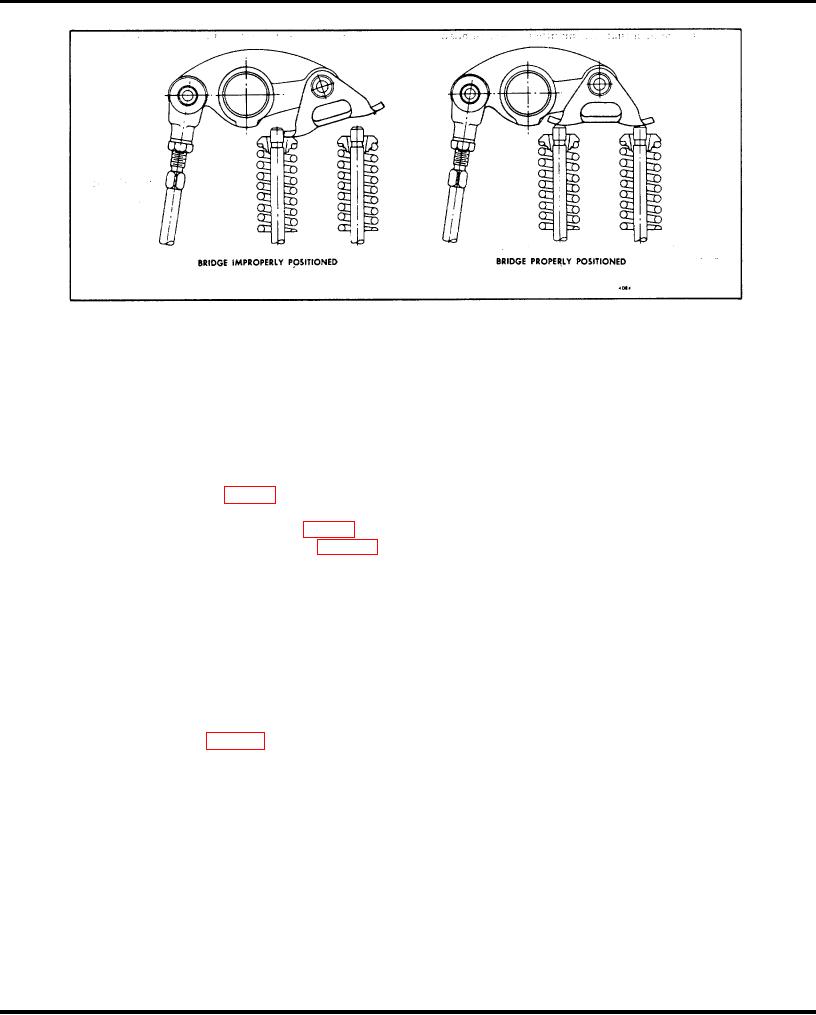

Fig. 12 - Relationship Between Exhaust Valve Bridge and Valve Stems

NOTE: Heat the Cindol 1705 in a small pail, with a screen insert. The screen

insert will prevent the follower assemblies from touching the bottom of the pail

during soaking, thus avoiding the possibility of contamination.

IMPORTANT: When installing a new cam follower assembly, wash it with clean

lubricating oil or Cindol 1705 to remove the preservative.

7. Note the oil hole in the bottom of the cam follower. With this oil hole pointing away from the exhaust valves, slide

the cam follower into position from the bottom of the head.

8. Attach the cam follower guide (Fig. 8) to the bottom of the cylinder head to hold the group of cam followers in place.

Tighten the cam follower guide bolts to 12-15 lb-ft torque. Check to be sure there is at least .005 " clearance between the

cam follower legs and the cam follower guide (Fig. 9). If there is insufficient clearance, loosen the guide bolts slightly and

tap each corner of the guide with a brass rod (Fig. 10). Then retighten the bolts to 12-15 lb-ft torque and recheck the

clearance.

Install Cam Follower and Push Rod Assembly (Cylinder Head Not Removed from Engine)

1. Lubricate the cam follower as stated in Step 6 under Install Cam Follower and Push Rod Assembly (Cylinder Head

Removed from Engine).

2. Note the oil hole in the bottom of the cam follower. With this hole pointing away from the exhaust valves, slide the

cam follower into position.

3. Install a serrated lower spring seat on each push rod. If the engine being assembled was equipped with plain lower

spring seats, replace them with serrated spring seats.

4.

Place the push rod springs (Fig. 11) on the push rods.

5. Install the proper upper spring seat on each push rod. The cup shaped spring seat used with the current type push

rod spring may also be used with the former spring.

6.

Set the push rod, lower spring seat, spring and upper spring seat down in the cam follower.

7. Install a flat washer and nut on the push rod. Then place tool J 3092-01 on the push rod, between the flat washer

and upper spring seat. Screw the nut down on the push rod until the spring is compressed sufficiently to permit the

retainer to be installed. Partially collapse the retainer and install it in the cylinder head groove.

8.

Remove the nut, flat washer and tool from the push rod.

9. Reinstall the nut on the push rod. Screw the nut down as far as possible on the push rod. Then screw the rocker arm

clevis down on the push rod until the end of the push rod is flush with or above the inner side of the clevis.

NOTE: The injector rocker arm (the center arm of the group) is slightly different

from the exhaust valve rocker arms; the boss for the

July, 1972

SEC. 1.2.1

Page 7