Engine Tune-Up

DETROIT DIESEL

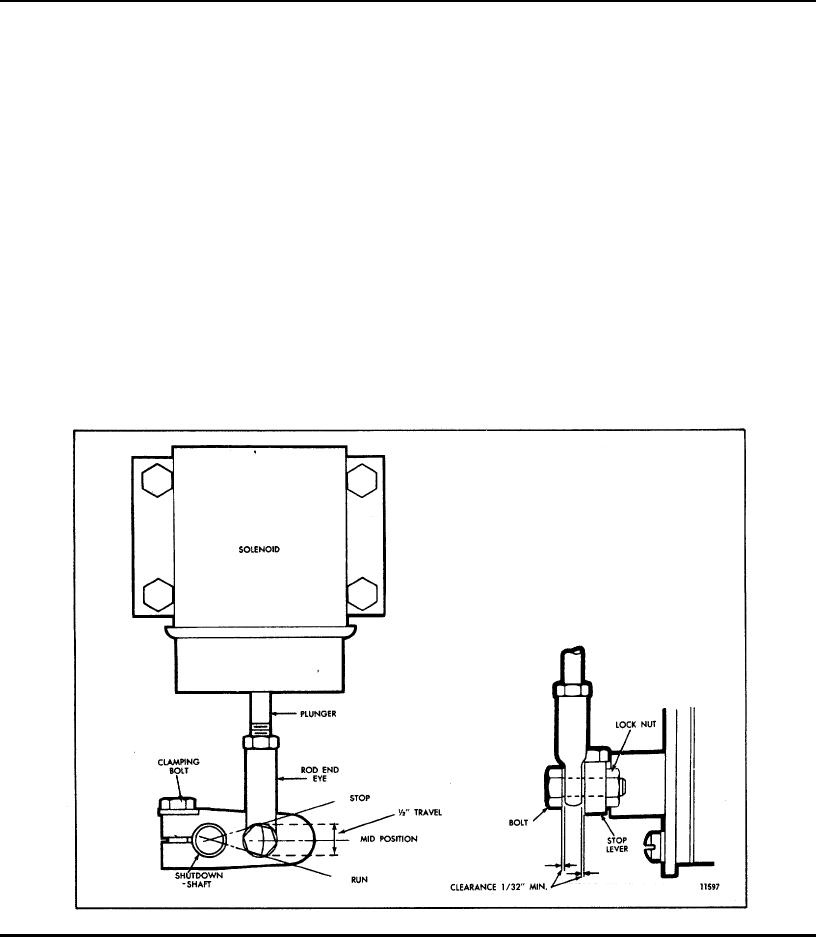

ADJUSTMENT OF MECHANICAL GOVERNOR SHUTDOWN SOLENOID

When a governor shutdown solenoid is used on an engine equipped with a mechanical governor, the governor stop lever

must be properly adjusted to match the shutdown solenoid plunger travel.

The solenoid plunger can be properly aligned to the governor stop lever as follows:

1. Remove the bolt connecting the rod end eye (variable speed governor), or the right angle clip (limiting speed

governor) to the stop lever (Figs. 6 and 7). Align and clamp the lever to the shutdown shaft in such a way that, at its

mid-travel position, it is perpendicular to the solenoid plunger. This assures that the linkage will travel as straight as

possible. The solenoid plunger has available 1/2" travel which is more than adequate to move the injector control racks

from the full-fuel to the complete no-fuel position and shutdown will occur prior to attaining complete travel.

2. With the' stop lever in the run -position, adjust the rod end eye or right angle clip for minimum engagement on the

solenoid plunger when the connecting bolt is installed. The oversize hole in the eye or clip will thereby permit the

solenoid to start closing the air gap, with a resultant build-up of pull-in force prior to initiating stop lever movement.

3. The bolt through the rod end eye or the right angle clip should be locked to the stop lever and adjusted to a height

that will permit the eye or clip to float vertically. The clearance above and below the eye or clip and the bolt head should

be approximately 1/32" minimum.

NOTE: The lock nut can be either on top of or below the stop lever.

4. Move the lever to the stop position and observe the plunger for any possible bind. If necessary, loosen the Fig. 6 -

Typical Variable Speed Governor Lever Position

Fig. 6 - Typical Variable Speed Governor Lever Position

Page 106