Engine Tune-Up

DETROIT DIESEL

lever in the run position and press down on the injector rack with a screw driver or finger tip and note the "rotating"

movement of the injector control rack (Fig. 4). Hold the stop lever in the run position and, using a screw driver, press

downward on the injector control rack. The rack should tilt downward (Fig. 5) and when the pressure of the screw driver

is released, the control rack should "spring" back upward. If the rack does not return to its original position, it is too loose.

To correct this condition, back off the outer adjusting screw slightly and tighten the inner adjusting screw. The setting is

too tight if, when moving the stop lever from the stop to the run position, the injector rack becomes tight before the

governor stop lever reaches the end of its travel. This will result in a step- up in effort required to move the stop lever to

the run position and a deflection in the fuel rod (fuel rod deflection can be seen at the bend). If the rack is found to be

too tight, back off the inner adjusting screw slightly and tighten the outer adjusting screw.

6. Remove the clevis pin from the fuel rod and the left bank injector control tube lever.

7. Insert the clevis pin in the fuel rod and the right cylinder bank injector control tube lever and position the No. 3R

injector rack control lever as previously outlined in Step 4 for the No. 3L control lever.

8. Insert the clevis pin in the fuel rod and the left bank injector control tube lever. Repeat the check on the 3L and 3R

injector rack control levers as outlined in Step 5. Check for and eliminate any deflection which may occur at the bend in

the fuel rod where it enters the cylinder head.

9. To adjust the remaining injector rack control levers, remove the clevis pin from the fuel rods and the injector control

tube levers, hold the injector control racks in the full-fuel position by means of the lever on the end of the control tube

and proceed as follows:

a. Turn down the inner adjusting screw of the injector rack control lever until the screw bottoms (injector control rack

in the full-fuel position).

b. Turn down the outer adjusting screw of the injector rack control lever until it bottoms on the injector control tube.

c. While still holding the control tube lever in the full-fuel position, adjust the inner and outer adjusting screws to

obtain the same condition as outlined in Step 5. Tighten the screws.

CAUTION: Once the No. 3L and No. 3R injector rack control levers are adjusted,

do not try to alter their settings. All adjustments are made on the remaining control

racks.

10. When all of the injector rack control levers are adjusted, recheck their settings. With the control tube lever in the

full-fuel position, check each control rack as in Step 5. All of the control racks must have the same "spring" condition

with the control tube lever in the full-fuel position.

11. Insert the clevis pin in the fuel rods and the injector control tube levers.

12. Use new gaskets and install the valve rocker covers.

Adjust Maximum No-Load Speed

All governors are properly adjusted before leaving the factory. However, if the governor has been reconditioned or

replaced, and to ensure the engine speed will not exceed the recommended no-load speed as given on -the engine

option plate, the maximum no-load speed may be set as follows:

Start the engine and after it reaches normal operating temperature, determine the maximum no-load speed of the engine

with an accurate tachometer. Then stop the engine and make the following adjustments, if required.

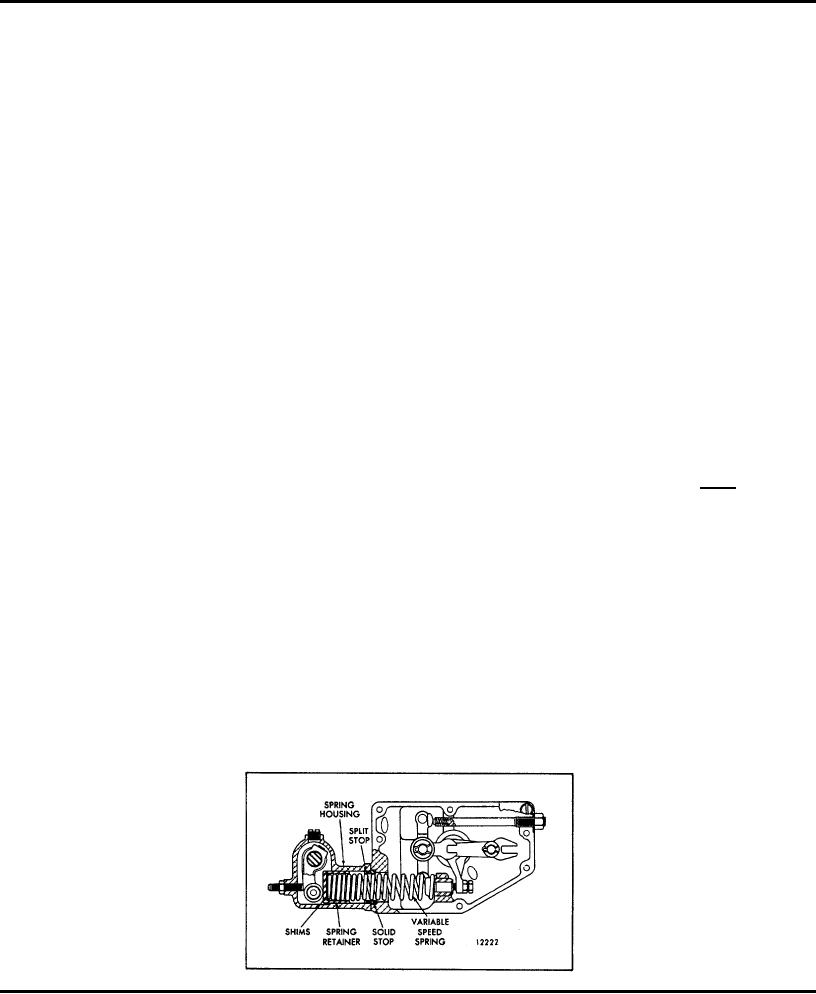

1. Refer to Fig. 9 and disconnect the booster spring and the stop lever retracting spring.

2. Remove the variable speed spring housing and the spring retainer, located inside of the housing, from the governor

housing.

3. Refer to Table 1 and determine the stops or shims required for the desired full-load speed. A split stop can only be

used with a solid stop (Fig. 6).

4. Install the variable speed spring retainer and housing and tighten the two bolts.

Fig. 6 - Location of Shims and Stops

Page 100