Fuel Oil and Coolant Specifications

DETROIT DIESEL

GENERAL CONSIDERATIONS

The quality of fuel oil used for high-speed diesel engine operation is a very important factor in obtaining satisfactory

engine performance, long engine life, and acceptable exhaust. Fuel selected should be completely distilled material.

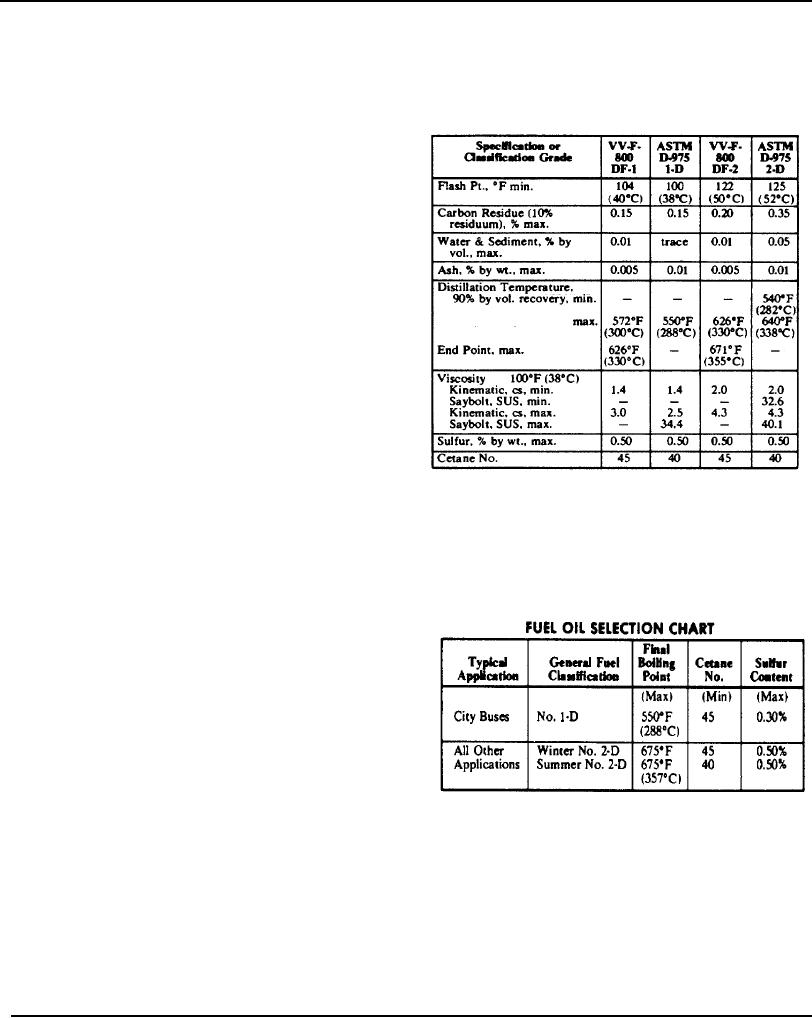

Fuels marketed to meet Federal Specification VV-F-800 (grades DF-I and DF-2) and ASTM Designation D-975 (grades I-

D and 2-D) meet the completely distilled criteria. Some of the general properties of VV-F-800 and ASTM D-975 fuels are

shown below.

FEDERAL SPECIFICATION A ASTMDIESEL FUEL PROPERTIES

Residual fuels and domestic furnace oils are not considered

satisfactory for Detroit Diesel engines; however, some may

be acceptable.

(See "DETROIT DIESEL FUEL OIL

SPECIFICATIONS").

NOTE: Detroit Diesel Allison does

not

recommend the use of drained lubricating oh as a

diesel fuel oil.

All diesel fuel oil contains a certain amount of sulfur. Too

high a sulfur content results in excessive cylinder wear due

to acid build-up in the lubricating oil. For most satisfactory

engine life, fuels containing less than 0.5% sulfur should be

used. Fuel oil should be clean and free of contamination.

Storage tanks should be inspected regularly for dirt, water or

water-emulsion sludge, and cleaned if contaminated.

Storage instability of the fuel can lead to the formation of

varnish or sludge in the tank. The presence of these

contaminants from storage instability must be resolved with

the fuel supplier.

SPECIFICATIONS

Detroit Diesel Allison designs, develops, and manufactures commercial diesel engines to operate on diesel fuels

classified by the ASTM as Designation D-975 (grades I-D and 2-D). These grades are very similar to grades DF-1 and

DF-2 of Federal Specification VV-F-800. Residual fuels and furnace oils, generally, are not considered satisfactory for

Detroit Diesel engines. In some regions, however, fuel suppliers may distribute one fuel that is marketed as either diesel

fuel (ASTM D-975) or domestic heating fuel (ASTMD-396) sometimes identified as furnace oil. In this case, the fuel

should be investigated to determine whether the properties conform with those shown in the "FUEL OIL SELECTION

HART" presented in this specification.

The "FUEL OIL SELECTION CHART" also will serve as a

guide in the selection of the proper fuel for various

applications. The fuels used must be clean, completely

distilled, stable, and non-corrosive. DISTILLATION RANGE,

CETANE NUMBER, and SULFUR CONTENT are three of

the most important properties of diesel fuels that must be

controlled to insure optimum combustion and minimum

wear.

Engine speed, load, and ambient temperature

influence the selection of fuels with respect to distillation

range and cetane number. The sulfur content of the fuel

must be as low

as possible to avoid excessive deposit formation, premature

wear, and to minimize the sulfur dioxide exhausted into the

atmosphere.

To assure that the fuel you use meets the required properties, enlist the aid of a reputable fuel oil supplier. The

responsibility for clean fuel lies with the fuel supplier as well as the operator. During cold weather engine operation, the

cloud point (the temperature at which wax crystals begin to form in diesel fuel) should be 10F (6C) below the lowest

expected fuel temperature to prevent clogging of the fuel filters by wax crystals. At temperatures below -20F (-29C),

consult an authorized Detroit Diesel Allison service outlet, since particular attention must be given to the cooling system,

lubricating system, fuel system, electrical system, and cold weather starting aids for efficient engine starting and

operation.

NOTE: When prolonged idling periods or cold weather conditions below 32F (0C) are encountered, the use of lighter

distillate fuels may be more practical. The same consideration must be made when operating at altitudes above 5,000 ft.

Page 66