14.3.1

DETROIT DIESEL 53

LIMITING SPEED MECHANICAL GOVERNOR AND

INJECTOR RACK CONTROL ADJUSTMENT

IN-LINE ENGINE

After adjusting the exhaust valves and timing the fuel

injectors, adjust the governor and position the injector

rack control levers.

NOTE: Loosen the Ioad Iimit lever for the load

limiting device, if the engine is so equipped.

the governor

before

proceeding

with

adjustment.

Adjust Governor Gap

With the engine stopped and at operating tempera-

ture, adjust the governor gap as follows:

1. Remove the high speed spring retainer cover.

2. Back out the buffer screw until it extends 5/8"

beyond the governor housing.

3. Clean and remove the valve rocker cover.

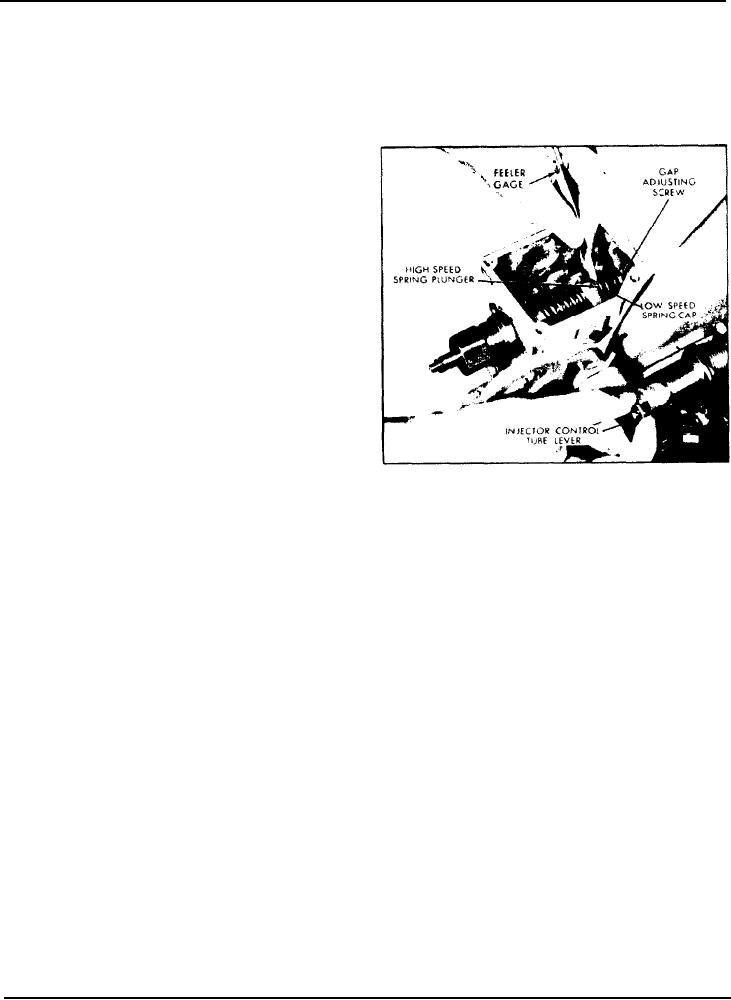

Fig. 1 - Adjusting Governor Gap

4. Start the engine and adjust the idle speed screw

(Fig. 5) to obtain an idle speed of 500-600 rpm.

10. Install the governor cover. The governor cover

should be placed on the housing with the pin of the

NOTE: The recommended idle speed is 500-600

speed control lever projecting into the slot of the

rpm, but may vary with special engine

differential lever.

applications.

11. Install the screws and lock washers finger tight. Pull

the cover away from the engine and tighten the

5. Stop the engine and remove the governor cover.

screws. This step will properIy locate the cover on the

governor housing.

6. Start the engine and control the speed manually by

operating the injector control tube lever. The engine

speed should be between 800 and 1000 rpm.

Position Injector Rock Control levers

CAUTION: Do not overspeed the engine.

The position of the injector racks must be correctly set

in relation to the governor. Their position determines

the amount of fuel injected into each cylinder and

7. Check the gap between the low speed spring cap

ensures equal distribution of the load.

and the high speed spring plunger with a .0015"

feeler gage. If the gap setting is incorrect, reset the

Adjust the rear injector rack control lever first to

gap adjusting screw (Fig. 1). If the setting is correct.

establish a guide for adjusting the remaining injector

the .0015" movement can be seen by placing a few

rack control levers.

drops of oil into the governor gap and pressing a

1. Disconnect any Iinkage attached to the speed control

screw driver against the gap adjusting screw.

lever.

Movement of the cap toward the plunger will force the

oil from the gap in the form of a small bead.

2. Loosen all of the inner and outer injector rack

control lever adjusting screws (Fig. 2) Be sure all of

8. Hold the gap adjusting screw and tighten the lock

the levers are free on the injector control tube.

nut.

3. Move the speed control lever to the full-fuel

9. Recheck the gap and readjust if necessary.

May, 1971 SEC. 14.3.1 Page 1