1.7.1 Gear Train and Timing

DETROIT DIESEL 53

the idler gear bearing.

lubrication

The gear train is lubricated by the overflow of oil

I

from the camshaft and balance shaft pockets spilling

into the gear train compartment A certain amount of

the oil also spills into the gear train compartment

from the camshaft and balance shaft end bearings and

ENGINE TIMING

The correct relationship between the crankshaft and

spindle movement of at least I". Provide an extension

for the indicator spindle. The extension must be long

camshaft(s) must he maintained to properly control

fuel injection end the opening and closing of the

enough to contact the piston just before it reaches the

exhaust valves.

end of its upward stroke. Also. select suitable

mounting attachments for the indicator so it can be

The crankshaft timing gear can he mounted in only

mounted over the injector tube in the cylinder head.

one position since it is keyed to the crankshaft. The

camshaft gear(s) can also he mounted in only one

6. Mount the indicator over the injector tube. Check to

position due to the location of the keyway relative to

he sure the indicator spindle extension is free in the

the cams. Therefore, when the engine is properly

injector tube and is free to travel at least one inch.

timed. the markings on the various gears will match as

shown in Fig 1.

7. Attach a suitable pointer to the engine lower front

cover. The outer end of the pointer should extend out

Pre-ignition. uneven running and a loss of power may

over the top of the crankshaft pulley.

result if an engine is "out of time".

When an engine is suspected of being out of time, due

8. Turn the crankshaft slowly, in the direction of

IO an improperly assembled gear train. a quick check

engine rotation, until the indicator hand just stops

can he made without removing the flywheel and

moving.

flywheel housing by following the procedure outlined

below.

9. Continue IO turn the crankshaft, in the direction of

rotation, until the indicator starts to move again . Now

set the indicator on zero and continue to turn the

Chock Engine liming

crankshaft until the indicator reading is .010"

Access to the crankshaft pulley. to mark the top dead

center position of the selected piston. and to the front

end of the crankshaft or the flywheel for turning the

crankshaft is necessary when performing the timing

check. Then, proceed as follows:

1. Clean and remove the valve rocker cover.

2. Select any cylinder for the timing check.

3. Remove the injector as outlined in Section 2.1 or

2.1.1.

4. Carefully slide a rod. approximately 12" long,

through the injector tube until the end of the rod rests

on top of the piston. Place the throttle in the no-fuel

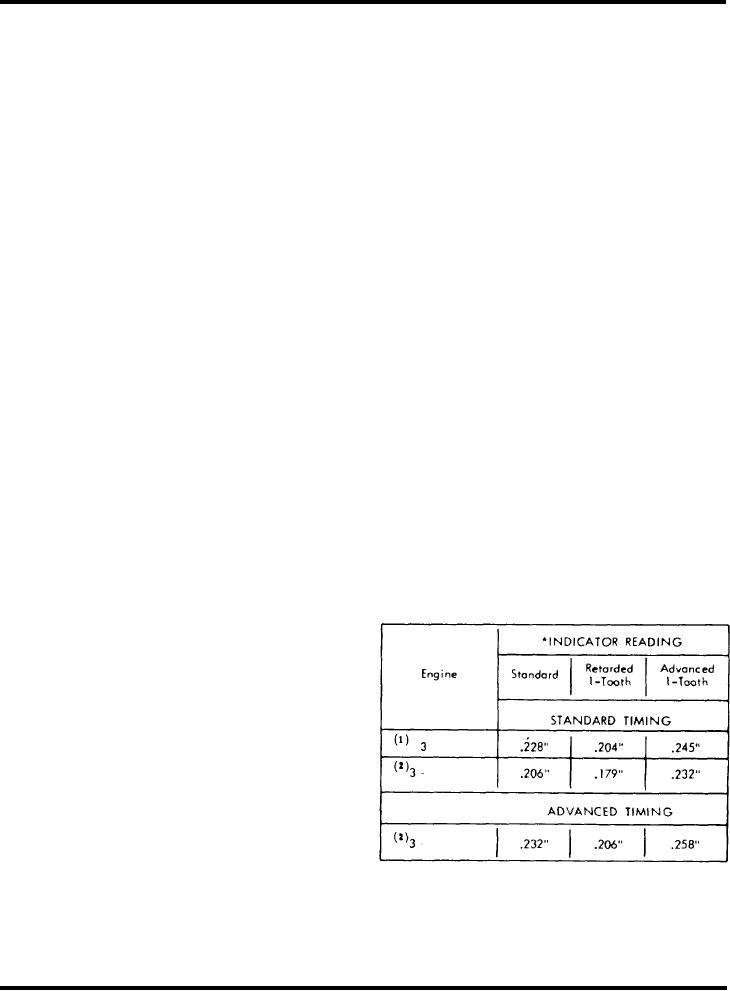

* Indicator readings shown ore nominal valuer. The

position. Then, turn the crankshaft slowly in the

allowable tolerance is .005 in.

direction of engine rotation. Stop when the rod

(1) High velocity type injector corn.

reaches the end of its upward travel. Remove the rod

(2) Low velocity type injector cam.

and turn the crankshaft, opposite the direction of

rotation, between 1/16 and 1/8 of a turn.

TABLE 1

5. Select a dial indicator with .001" graduations and a

Page 4