DETROIT DIESEL 53

1.3.4

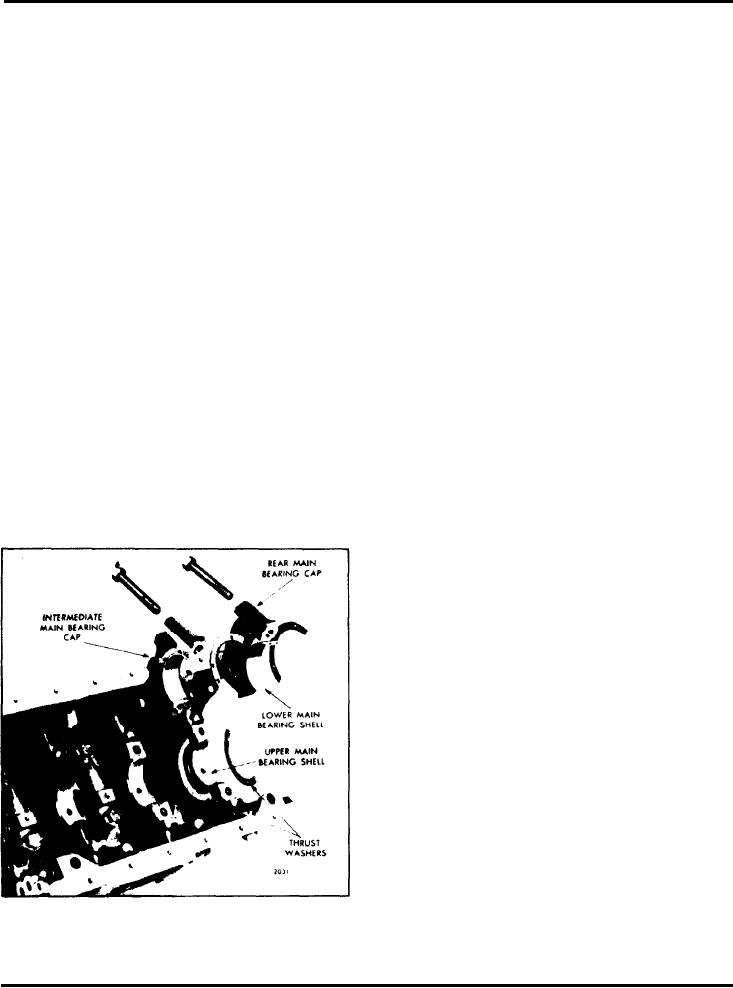

CRANKSHAFT MAIN BEARINGS

The crankshaft main bearing shells (Figs. 1 and 2) are

precision made and are replaceable without machin-

ing. They consist of an upper bearing shell seated in

each cylinder block main bearing support and a lower

bearing shell seated in each main bearing cap. The

bearing shells are prevented from endwise or radial

movement by a tang at the parting line at one end of

each bearing shell. The tangs on the lower bearing

shells are off-center and the tangs on the upper

bearing shells are centered to aid correct installation.

On In-line

engines, a 7/16" oil hole

in the groove of each upper bearing shell, midway

between the parting lines, registers with a vertical oil

passage in the cylinder block. Lubricating oil, under

pressure, passes from the cylinder block oil gallery by

way of the bearing shells to the drilled passages in the

crankshaft, then to the connecting rods and connecting

rod bearings.

Fig. 1 - Main Bearing Shells, Bearing Caps

and Crankshaft Thrust Washers -- In-Line

Engines

SEC. 1.3.4 Page 1

April. 1974