DETROIT DIESEL 53

1.2.1 Valve Operating Mechanism

4. Prior to installing a new roller and pin, remove any

.010 " diametric clearance exists, replace the cam

burrs on the surfaces of the cam follower at the pin

follower assembly or install a new cam roller and pin,

holes.

which are serviced as a set. Be sure the follower legs

are beveled (Fig. 6) and check the total side clearance

5. Position the follower body in the groove of the

between the roller and follower; this clearance must

fixture with the proper size fixture plunger extending

not be less than ,015 " nor more than .023 ".

through the roller pin hole in one of the legs of the

follower body.

Oversize roller and pin sets are available for service

when required. However, DO NOT attempt to bore out

6. Position the roller in the cam follower body

the legs of a standard cam follower for an oversize

(Fig. 7). The small plunger in the tool will align the

roller and pin set. This cannot be over emphasized

roller with the pin holes in the follower body.

because of the extremely close manufacturing

tolerances.

7. Align the pin with the hole in the follower body and

carefully drive the pin into the body until the ends of

NOTE: Cam follower assemblies with the letter

the pin are centered in the legs of the body.

"S" stamped on the end of the roller, pin and

on one leg of the cam follower body are

8. Check the side clearance between the roller and the

equipped with oversize roller and pin sets.

follower body. This clearance must be .015 " to .023 ".

Remove and Install Cam Follower Roller and

Install Cam Follower and Push Rod Assembly

Pin

(Cylinder Head Removed from Engine)

1. Clamp fixture J 5840 securely in a vise as shown in

1. Install a serrated lower spring seat on each push

Fig. 7 and place the cam follower in the groove in the

rod. If the engine being assembled was equipped with

top of the fixture with the follower pin resting on top

plain lower spring seats, replace them with serrated

of the corresponding plunger in the fixture.

spring seats (Fig. 8).

2. Drive the pin from the roller with a suitable drift.

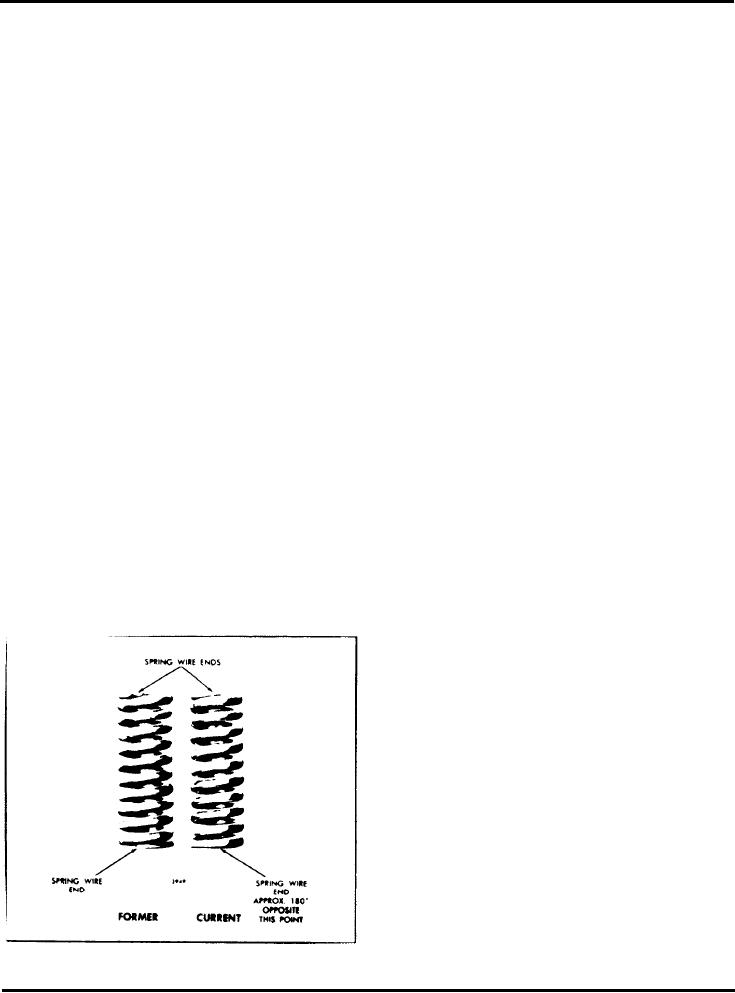

2. Place the push rod springs (Fig. 11) on the push

Exercise caution in removing the cam follower body

rods.

and roller from the fixture as the follower pin is seated

on top of a spring-loaded plunger in the fixture body.

3. Install the proper upper spring seat on each push

rod. The cup shaped spring seat used with the current

3. Before installing the new roller and pin kit, remove

type push rod spring may also be used with the former

spring.

the preservative by washing the parts with clean

lubricating oil or Cindol 1705. Do not use fuel oil.

4. Install the spring seat retainer in the cylinder head.

Then slide the push rod, lower spring seat, spring and

upper spring seat as an assembly into the cam follower

bore from the bottom of the cylinder head.

5. Screw the push rod lock nut down on the upper end

of the push rod as far as possible. Then screw the push

rod into the clevis until the end of the rod is flush with

or above the inner side of the clevis.

6. Immerse the cam follower assemblies in clean

Cindol 1705 (heated to 100o-125oF.) for at least one

hour before placing them in the cylinder head, to

ensure initial lubrication between the cam follower

roller pins and the roller bushings. Rotate the cam

follower roller during the soaking period to aid in

purging any air from the bushing-roller area. The

heated Cindol 1705 results in better penetration as it

is less viscous than engine oil and flows more easily

between the pin and roller bushing surfaces. After the

cam follower is removed from the Cindol 1705, the

cooling action of any trapped air in the pin and

Fig. 11 - Push Rod Spring ldentification

bushing area tends to pull the oil into the cavity.

Page 6