DETROIT DIESEL

Engine Tune-Up

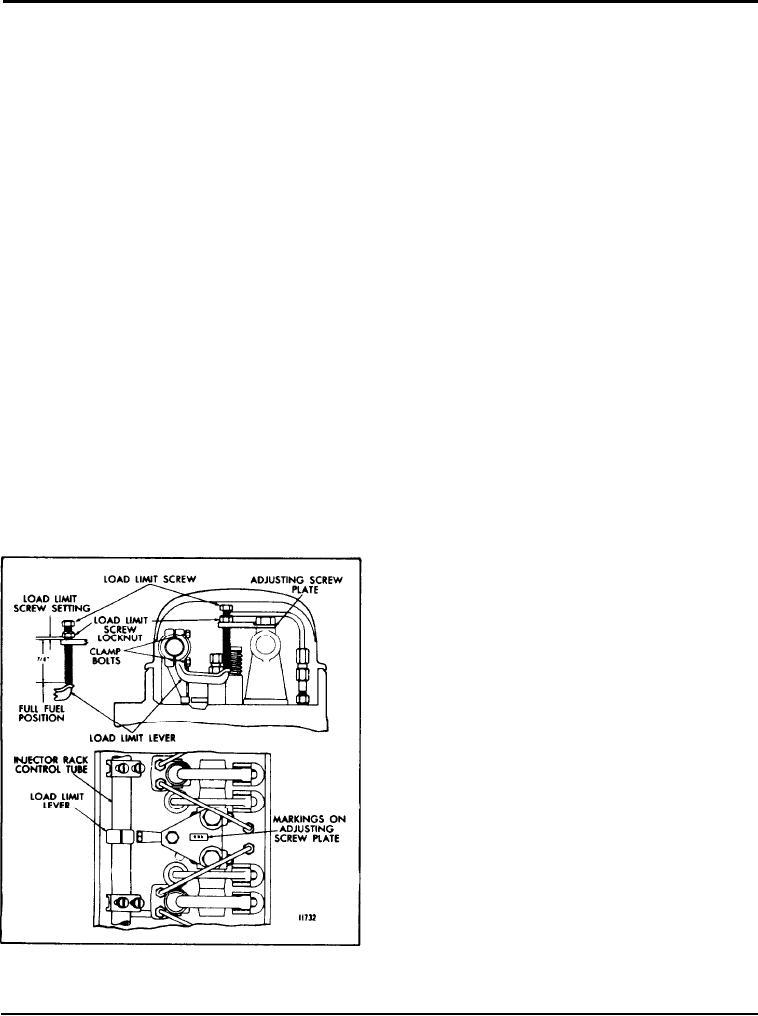

SUPPLEMENTARY GOVERNING DEVICE ADJUSTMENT

ENGINE LOAD LIMIT DEVICE

Engines with mechanical governors may be equipped

Adjustment

with a load limit device (Fig. 1) to reduce the

After the engine tune-up is completed, make sure the

maximum horsepower.

load limit device is properly installed as shown in

Fig. 1. Make sure the counterbores in the adjusting

This device consists of a load limit screw threaded into

screw plate are up. The rocker arm shaft bracket bolts

which fasten the adjusting screw plate to the brackets

a plate mounted between two adjacent rocker arm

are tightened to 50-55 lb-ft (68-75 Nm) torque. Then

shaft brackets and a load limit lever clamped to the

adjust the load limit device, on each cylinder head, as

injector control tube.

follows:

1. Loosen the load limit screw lock nut and remove the

The load limit device is located between the No. 2 and

screw.

No. 3 cylinders of a three or four cylinder engine or

2. Loosen the load limit lever clamp bolts so the lever

between the No. 1 and No. 2 cylinders of each

is free to turn on the injector rack control tube.

cylinder head on a V-type engine. However, when

valve rocker covers with a breather are used, the load

3. With the screw out of the plate, adjust the load limit

screw lock nut so the bottom of the lock nut is

limit device is installed between the No. 1 and No. 2

7/8" from the bottom of the load limit screw (Fig. I)

cylinders on in-line engines and between the No. 2

for the initial setting.

and No. 3 cylinders on V-type engines to avoid

interference with the rocker cover baffles.

4. Loosen the load limit lever clamp bolts so the lever

is free to turn on the injector rack control tube.

When properly adjusted for the maximum horsepower

4. Thread the load limit screw into the adjusting screw

desired, this device limits the travel of the injector

plate until the lock nut bottoms against the top of the

plate.

control racks and thereby the fuel output of the

injectors.

5. Hold the injector rack control tube in the full-fuel

position and place the load limit lever against the

bottom of the load limit screw. Then tighten the load

limit lever clamp bolts.

6. Check to ensure that the injector racks will just go

into the full-fuel position -- readjust the load limit

lever if necessary.

7. Hold the load limit screw to keep it from turning,

then set the lock nut until the distance between the

bottom of the lock nut and the top of the adjusting

screw plate corresponds to the dimension (or number

of turns) stamped on the plate. Each full turn of the

screw equals .042", or .007" for each flat on the

hexagon head.

NOTE: If the plate is not stamped, adjust the

load limit screw while operating the engine on a

dynamometer test stand and note the number

o f turns required to obtain the desired

horsepower. Then stamp the plate accordingly.

8. Thread the load limit screw into the plate until the

lock nut bottoms against the top of the plate. Be sure

the nut turns with the screw.

9. Hold the load limit screw to keep it from turning,

Fig. 1 - Engine Load Limit Device

then tighten the lock nut to secure the setting.

Page 103