Engine Tune-Lb

DETROIT DIESEL

The letters R or L indicate the injector location in the

adjusting screw (Fig. 2). If the setting is correct, the

right or left cylinder bank, viewed from the rear of the

.0015" movement can be seen by placing a few drops

of oil into the governor gap and pressing a screw

engine. Cylinders are numbered starting at the front

of the engine on each cylinder bank. Adjust the

driver against the gap adjusting screw. Movement of

No. 3L injector rack control lever first to establish a

the cap toward the plunger will force the oil from the

guide for adjusting the remaining injector rack control

gap in the form of a small bead.

levers.

7. Hold the gap adjusting screw and tighten the lock

nut.

1. Disconnect any linkage attached to the speed control

lever.

8. Recheck the gap and readjust if necessary.

2. Turn the idle speed adjusting screw until 1/2" of

the threads (12-14 threads) project from the lock nut

9. Stop the engine and, using a new gasket, install the

when the nut is against the high-speed plunger.

governor cover.

CAUTION: A false fuel rack setting may result

if the idle speed adjusting screw is not backed

Position Injector Rack Control Lovers

out as noted above.

The position of the injector racks must be correctly set

NOTE: This adjustment lowers the tension of

in relation to the governor. Their position determines

the low-speed spring so it can be easily

the amount of fuel injected into each cylinder and

compressed. This permits closing the low speed

ensures equal distribution of the load.

gap without bending the fuel rods or causing

the yield mechanism springs to yield or stretch.

Properly positioned injector rack control levers with

the engine at full-load will result in the following:

3. Back out the buffer screw approximately 5/8", if it

has not already been done.

1. Speed control lever at the maximum speed position.

4. Remove the clevis pin from the fuel rod and the

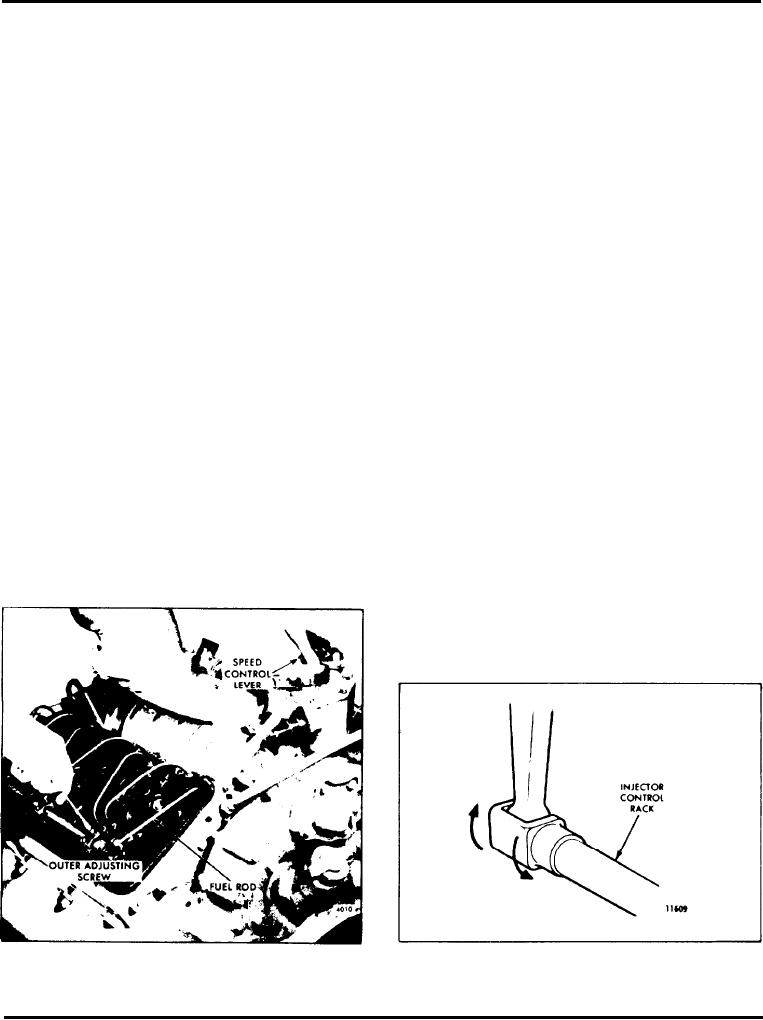

2. Governor low-speed gap closed.

right cylinder bank injector control tube lever.

3. High-speed spring plunger on the seat in the

5. Loosen all of the inner and outer injector rack

governor control housing.

control lever adjusting screws on both injector control

tubes. Be sure all of the injector rack control levers are

4. Injector fuel control racks in the full-fuel position.

free on the injector control tubes.

6. Move the speed control lever to the maximum speed

position; hold it in that position with light finger

pressure. Turn the inner adjusting screw on the

Fig. 4 - Checking Rotating Movement of

Fig. 3 - Positioning No. 3L Injector Rack

Injector Control Rack

Control Lever

Page 85