DETROIT DIESEL

Engine Tune-Up

LIMITING SPEED MECHANICAL GOVERNOR AND INJECTOR RACK

CONTROL ADJUSTMENT

IN-LINE ENGINES

The double-weight limiting speed governor is mounted

3. Start the engine and adjust the idle speed screw

on the rear end plate of the engine and is driven by a

(Fig. 7) to obtain the desired engine idle speed. Hold

gear that extends through the end plate and meshes

the screw and tighten the lock nut to hold the

with either the camshaft gear or the balance shaft

adjustment.

gear, depending upon the engine model.

NOTE: The recommended idle speed for non-

After adjusting the exhaust valves and timing the fuel

EPA certified engines is 500-600 rpm, but may

injectors, adjust the governor and position the injector

vary with special engine applications.

rack control levers.

4. Stop the engine, clean and remove the governor

cover and the valve rocker cover. Discard the gaskets.

NOTE: Before proceeding with the governor and

injector rack adjustments, disconnect any

5. Start and run the engine, between 800 and 1000 rpm

supplementary governing device. After the

by manual operation of the injector control tube lever.

adjustments are completed, re-connect and

adjust the supplementary governing device.

CAUTION: Do not overspeed the engine.

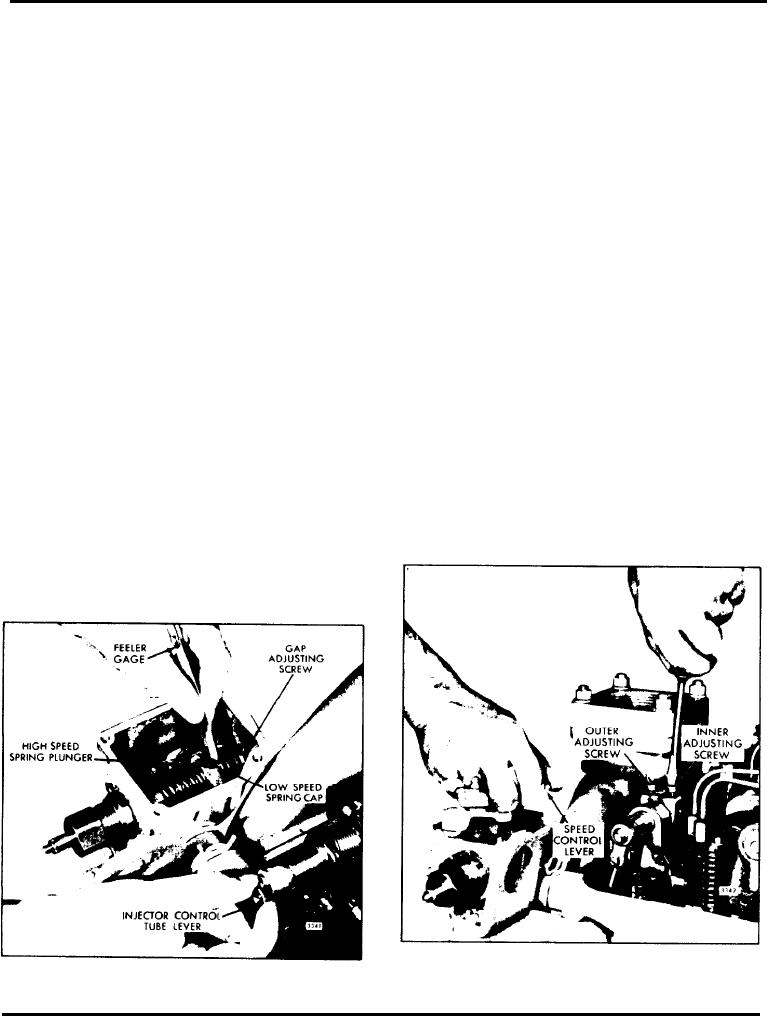

6. Check the gap between the low-speed spring cap

and the high-speed spring plunger with a .0015" feeler

Adjust Governor Gap

gage. If the gap setting is incorrect, reset the gap

adjusting screw (Fig. 1). If the setting is correct, the

With the engine stopped and at operating tempera-

.0015" movement can be seen by placing a few drops

ture, adjust the governor gap as follows:

of oil into the governor gap and pressing a screw

driver against the gap adjusting screw. Movement of

1. Remove the high-speed spring retainer cover.

2. Back out the buffer screw (Fig. 8) until it extends

approximately 5/8" from the lock nut.

Fig. 2 - Positioning the Rear Injector Rack

Fig. 1 - Adjusting Governor Gap

Control Lever

Page 79