DETROIT DIESEL

Engine Equipment

Clutch

Hand Lever

Pressure

Torque

Diameter

Length

PSI

kPa

lb-ft

Nm

8"

15 1/2"

55

379

56-63

76-85

10"

15 1/2"

87-94

80

552

113-127

*11 1/2"

15 3/8"

100

689

129

175

11 1/2"

20"

105

724

112-120

152-163

*Twin Disc Clutch

TABLE 1

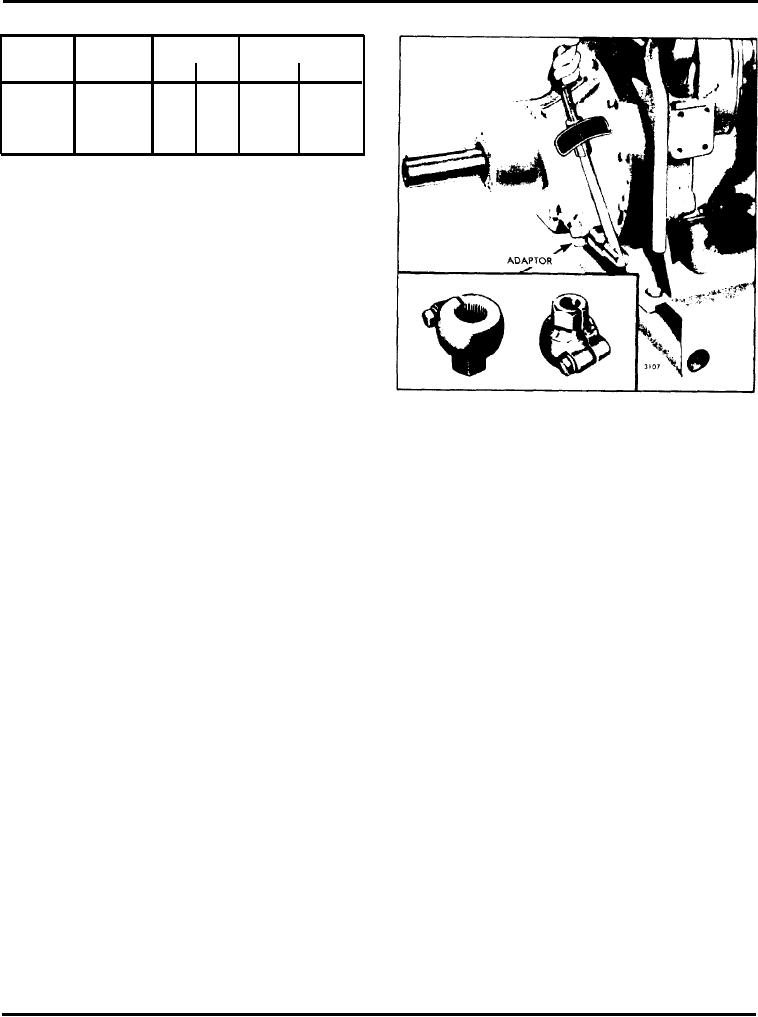

clutch release shaft (Fig. 11), is obtained as shown in

Table 1.

When properly adjusted, the approximate pressure

required at the outer end of the hand lever to engage

the various diameter clutches is shown in the table.

These specifications apply only with the hand lever

which is furnished with the power take-off,

A suitable spring scale may be used to check the

pounds pressure required to engage the clutch.

However, a more accurate method of checking the

Fig. 11 - Checking Clutch Adjustment with a

clutch adjustment is with a torque wrench as shown in

Torque Wrench and Adaptor

Fig. 11.

Make a final clutch adjustment with the engine

To fabricate an adaptor, saw the serrated end off of a

running as follows:

clutch hand lever and weld a 1-1/8" nut (across the

hex) on it as shown in Fig. 11. Then saw a slot

1. Start the engine and operate it at idling speed

through the nut.

(approximately 500 rpm) with the clutch disengaged.

The speed will be sufficient to move the segments out

When checking the clutch adjustment with a torque

to the operating position.

wrench, engage the clutch slowly and note the amount

of torque immediately before the clutch engages (goes

2. Check the pressure required to engage the clutch.

over center). The specified torque is shown in Table 1.

The engagement pressure should be the same as that

following the adjustment. If the clutch engages at a

CAUTION: The thrust load on the bronze clutch

lower pressure, the adjustment was probably made

release bearing should be kept at an absolute

against the unworn portion of the facing.

minimum. Therefore, the hand lever should be

positioned on the shaft as near the 12 o clock or

3. Stop the engine and readjust the clutch. making sure

6 o clock position as possible. The 9 and 3

all disc segments are properly positioned. Install the

o clock positions are to be avoided.

inspection hole cover.

TORQMATIC CONVERTERS

The Torqmatic converter is a self contained unit which

lock-up clutch, a manual input disconnect clutch, and

transfers and multiplies the torque of the prime

an accessory drive for either a governor or tachometer.

mover. This unit transmits the power through the

Check the oil level daily. If the converter is equipped

action of oil instead of through gears and in addition

with an input disconnect clutch, additional checks and

to multiplying the torque also acts as a fluid coupling

service will be necessary daily or at intervals

between the engine and the equipment to be powered.

determined by the type of operation.

The converter will automatically adjust the output

torque to load requirements.

Adjust the disconnect clutches as outlined under power

take-off clutch adjustment.

T h e r e are various combinations of Torqmatic

converters with features such as: an automotive or

Contact an authorized Detroit Diesel Allison Service

industrial flange on the shaft, a hydraulically operated

Outlet for service on Torqmatic converters.

Page 45