TM 5-3895-346-14

LUBRICATING OIL COOLER

ENGINE OVERHAUL

Clean the core before the sludge hardens. If the oil passages are badly clogged, circulate an Oakite or alkaline

solution through the core and flush thoroughly with clean, hot water.

2. Clean water side of Cooler - After cleaning the oil side of the core, immerse it in the following solution: Add

one-half pound of oxalic acid to each two and one-half gallons of solution composed of one-third muriatic acid

and two-thirds water. The cleaning action is evidenced by bubbling and foaming. Watch the process carefully

and, when bubbling stops (this usually takes from 30 to 60 seconds), remove the core from the cleaning

solution and thoroughly flush it with clean, hot water. After cleaning, dip the core in light oil.

CAUTION

Do not attempt to clean an oil cooler core when an engine failure

occurs in which metal particles from worn or broken parts are

released into the lubricating oil. Replace the oil cooler core.

Pressure Check Oil Cooler Core

After the oil cooler core has been cleaned, check for leaks as follows:

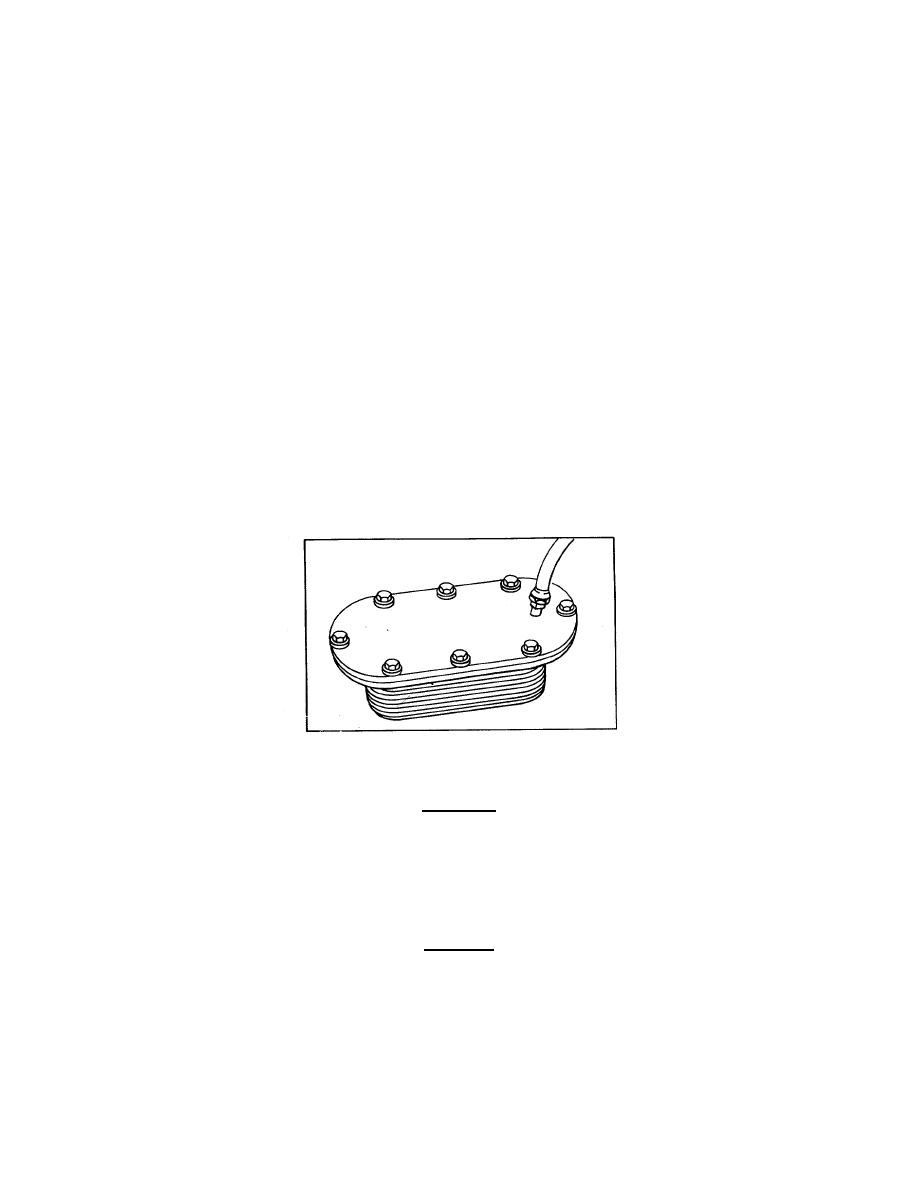

1. Make a suitable plate and attach it to the flanged side of the cooler core. Use a gasket made from rubber to

assure a tight seal. Drill and tap the plate to permit an air hose fitting to be attached at the inlet side of the core

(Fig. 1).

2. Attach an air hose, apply approximately 75-150 psi (517-1034 kPa) air pressure and submerge the oil cooler

core and plate assembly in a container of water heated to 180

F

Figure 1. Preparing Oil Cooler Core for Pressure Test

(82 ). Any leaks will be indicated by air bubbles in the water. If leaks are indicated, replace the core.

C

WARNING

When making this pressure test, be sure that personnel are

adequately protected against any stream of pressurized water

from a leak or rupture of a fitting, hose, or the oil cooler core.

3. After the pressure check is completed, remove the plate and air hose from the cooler core, then dry the core

with compressed air.

CAUTION

Where a leaking oil cooler core has caused contamination of the

engine, the engine must be immediately flushed to prevent

serious damage (refer to Cooling System).

Install Oil Cooler Core

1. If the oil cooler adaptor (in-line engines) was removed from the cylinder block, remove the old gasket

material from the bosses where the adaptor sets against the block. Affix new adaptor gaskets (Fig. 2), then

secure the adaptor to the cylinder block with five bolts and lockwashers.

320