TM 5-3895-346-14

ENGINE OVERHAUL

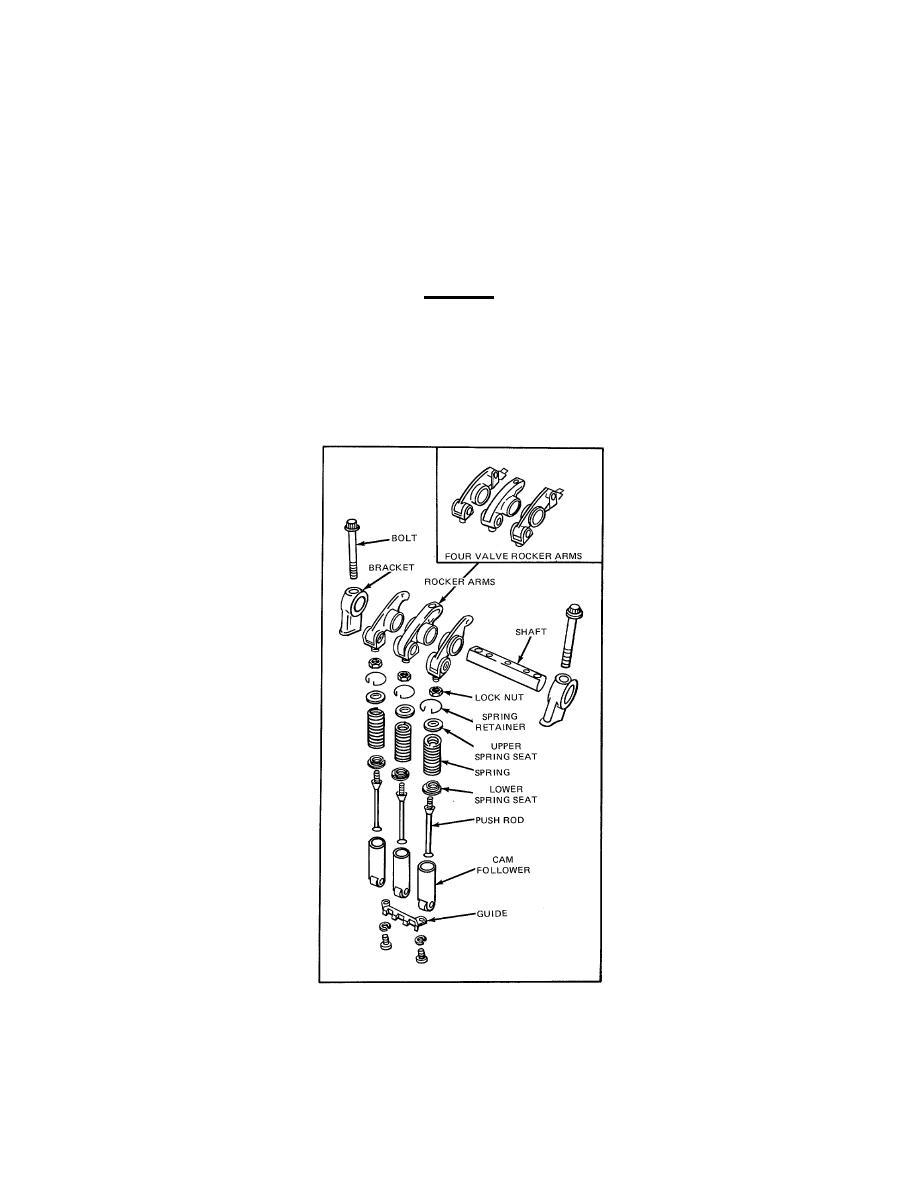

VALVE OPERATING MECHANISM

7. Remove the cam follower from the fixture and check the side clearance (Fig. 4). The clearance must be

0.011 to 0.023 inch.

Install Cam Follower and Push Rod

If new cam follower assemblies are to be installed, remove the preservative by washing with Cindol 1705 and

wipe dry. DO NOT USE FUEL OIL.

Before cam followers are installed, immerse them in clean Cindol 1705 (heated to 100-125 or 38-52 ) for at

F

C

least one hour to ensure initial lubrication of the cam roller pins and bushings. Rotate the cam rollers during the

soaking period to purge any air from the bushing-roller area. The heated Cindol oil results in better penetration

as it is less viscous than engine oil and flows more easily between the cam roller bushing and pin. After the

cam followers are removed from the heated Cindol 1705, the cooling action of any air trapped in the bushing

and pin area will tend to pull the lubricant into the cavity.

CAUTION

Heat the Cindol 1705 in a small pail with a screen insert. The screen will prevent

the cam followers from touching the bottom of the pail and avoid the possibility of

Install used cam followers and push rods in their original locations. Refer to Fig. 8 and proceed as follows:

CYLINDER HEAD ON ENGINE

1. Note the oilhole in the bottom of the cam follower. With the oilhole directed away from the exhaust

valves, slide the cam follower in position in the cylinder head.

2. Assemble the serrated lower spring seat, spring, and upper cupshaped spring seat on the push rod.

Figure 8. Valve and Injector Operating Mechanism and Relative Location of Parts

NOTE

The current cup-shaped upper spring seat can be used with either the former or

current spring.

3. Place a flat washer over the upper spring seat and start the locknut on the push rod. Place tool J 3092-01

on the push rod between the washer and

87