TM 5-3895-346-14

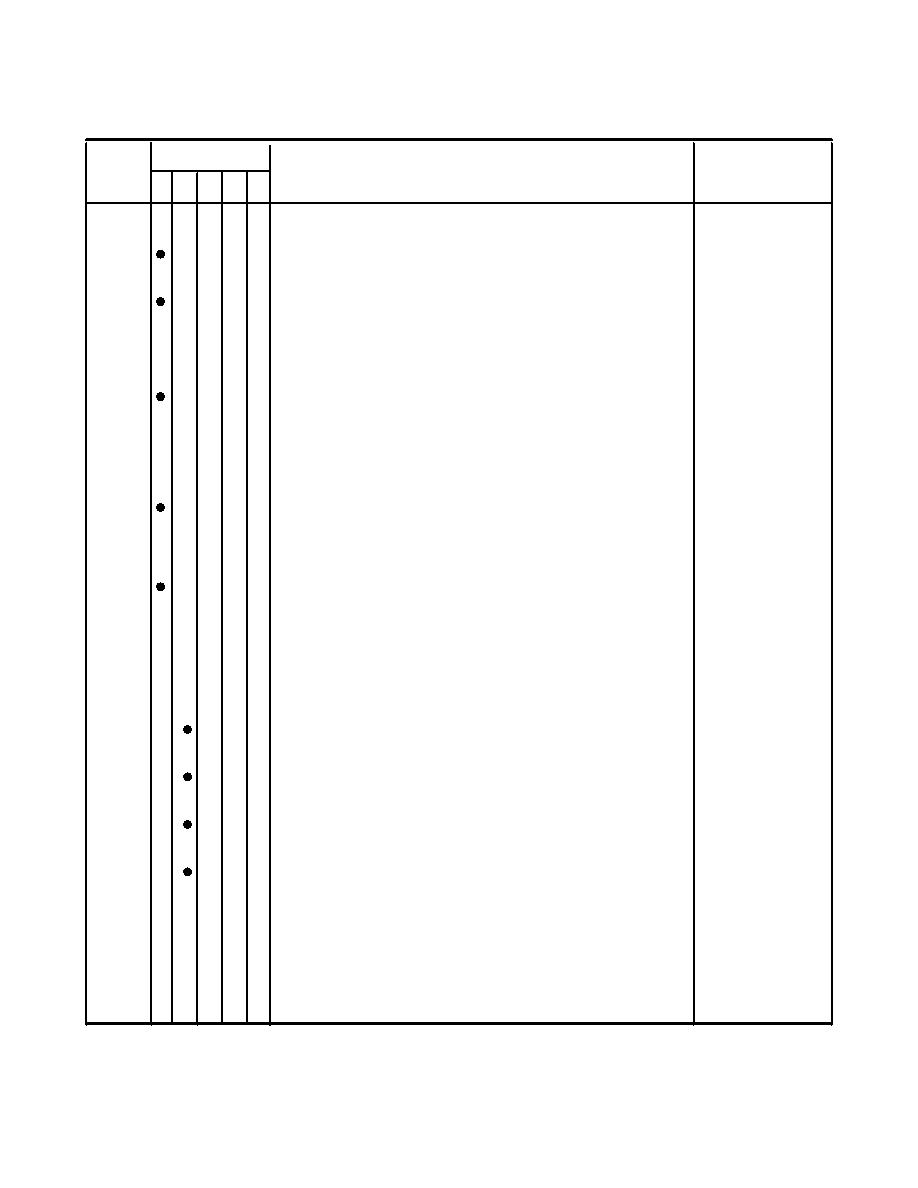

OPERATOR/CREW PREVENTIVE MAINTENANCE CHECKS AND SERVICES

B - Before

D - During

A - After

W - Weekly

M - Monthly

INTERVAL

ITEM TO BE INSPECTED PROCEDURE

EQUIPMNET IS

ITEM

CHECK FOR AND HAVE REPAIRED, FILLED,

NOT READY/

NO

B

DA W M

OR ADJUSTED AS NECESSARY

AVAILABLE IF:

5

TIRES (CONT)

b.

Check for correct air pressure

(16 psi).

6

ROLL SCRAPER

Check clearance between scraper and

Clearance incorrect.

roll. (Clearance should be approxi-

mately 7/8 inch.)

7

VIBRATING ROLL BUMPERS

Check clearance between rubber

Clearance incorrect.

bumper and suspension beam.

(Clearance should be approximately

1/8 inch.)

HYDROSTATIC DRIVE RESERVOIR

8

Check fluid level sight gage on

reservoir. Add as required.

9

ROLL AXLE BEARINGS

Lubricate until grease appears from

under seal in inner end of bushing

next to roll head.

10

CONTROLS AND INSTRUMENTS (Check for

Engine coolant, oil

proper indication and operation.)

pressure, or hy-

draulic oil tempera-

a.

Engine coolant temperature gage

ture gages indicate

160180 normal operation

-

F

abnormal operation.

b.

Engine Oil Pressure Gage

40-60 psi normal operation

c.

Slight ( + ) charge

d.

Hydraulic Oil Temperature Gage

100180 normal operation

-

F

26