e. Do not attempt to pave areas that are excessively rocky.

f. Never operate the engine under a continuous strain for long periods of time.

54.

Organizational Maintenance

a. Organizational preventive maintenance is performed by organizational maintenance personnel, with the aid of the

operator, at weekly and monthly intervals. The weekly interval will be equivalent to 60 hours of use. The monthly interval

will be equivalent to 4 weeks, or 240 hours, of use, whichever occurs first.

b. The technical inspection column is provided for the information and guidance of personnel performing technical

inspection, and constitutes the minimum inspection requirements for the equipment.

c. The preventive maintenance services -to be performed at these regular intervals are listed and described below.

The numbers appearing in the columns opposite each service refer to a corresponding number appearing on DA Form

464, and indicate that a report of the service should be made at that particular number on DA Form 464. These numbers

appear in either second, third, or both columns, as an indication of the interval at which the service is to be performed.

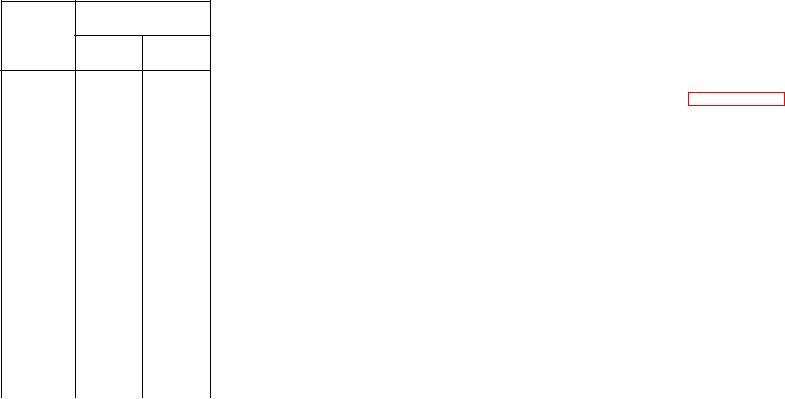

Tech-

nical

Service

inspec-

tion

Monthly Weekly

GENERAL

Before-operation services. Check and perform services described in paragraph 52c.

1

1

1

Lubrication. Inspect the entire unit for missing or damaged lubrication fittings, lines, and

2

2

2

grease cups, as well as for indications of insufficient lubrication.

2

2

Replace missing or damaged fittings, lines, and grease cups. Lubricate as specified in

LO 5-1185.

Tools and equipment. Inspect the condition of all tools and equipment assigned to the

3

3

3

unit. Check the condition and mounting of tool boxes and compartments.

3

3

See that all tools and equipment assigned to the unit are clean, serviceable, and

properly stowed or mounted. See that tool boxes or compartments are in good

condition and that they close and fasten properly.

Fire extinguisher. Check the fire extinguisher and inspect for full charge, proper

4

4

4

working order, and secure mounting. The amount of charge in the carbon dioxide

type of extinguisher can be checked only by weighing. Empty and full weights are

stamped on the valve head. The amount of charge in the carbon tetrachloride type

can be determined by shaking the extinguisher and judging by sound and weight

whether it is full.

4

4

See that any deficiencies are corrected or reported to the proper authority.

51