TM 5-3895-383-24

There is one intake and one exhaust valve for each cylinder.

Make reference to Valve System Components. The intake

valve opens when the piston moves down on the inlet stroke.

Compressed air from the inlet chamber is pulled into the

cylinder.

The intake valve closes and the piston starts to move up on the

compression stroke. When the piston is near the top of the

compression stroke, fuel is injected into the cylinder. The fuel

mixes with the air and combustion starts. The force of

combustion pushes the piston down on the power stoke.

When the piston moves up again it is on the exhaust stroke.

The exhaust valve opens and the exhaust gases are pushed

through the exhaust port into exhaust manifold (4). After the

piston makes the exhaust stroke, the exhaust valve doses and

the cycle (inlet, compression, power, exhaust) starts again.

Exhaust gases from the exhaust manifold go into the turbine

side of the turbocharger (5) and cause turbine wheel (9) to

turn. The turbine wheel is connected to the shaft that drives

compressor wheel (8). The exhaust gases then go out the

exhaust outlet (10).

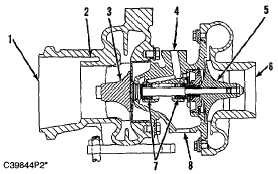

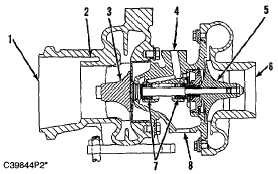

Turbocharger

Turbocharger Cross Section

(1) Exhaust outlet. (2) Exhaust bypass port. (3) Turbine

wheel. (4) Oil inlet port. (5) Compressor wheel. (6) Air inlet.

(7) Bearings. (8) Oil outlet port.

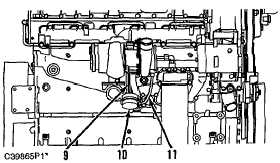

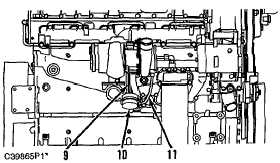

Waste Gate Turbocharger (if equipped)

(9) Actuating lever. (10) Case. (11) Line (boost pressure).

The turbocharger is mounted to the exhaust manifold of the

engine. All the exhaust gases go through the turbocharger.

The exhaust gases go into exhaust inlet of the turbine housing

and push the blades of turbine wheel (3). This causes the

turbine wheel and compressor wheel to turn at speeds up to

100 000 rpm.

Clean air from the air cleaner is pulled through the compressor

housing air inlet (6) by rotation of compressor wheel (5). The

action of the compressor wheel blades causes a compression

and heating of the inlet air. The hot compressed air from the

turbocharger is then cooled by the aftercooler before going to

the inlet manifold of the engine. This compression gives the

engine more power because it makes it possible for the engine

to burn additional fuel with greater efficiency.

Maximum rpm of the turbocharger is controlled by the fuel

setting, the high idle rpm setting and the height above sea level

at which the engine is operated.

When the engine is operating under low boost conditions a

spring pushes against a diaphragm in canister (10) and moves

actuating lever (9) to close the wastegate valve which will allow

the turbocharger to operate at maximum performance.

As the boost pressure increases against the diaphragm in

canister (10), the wastegate valve is opened and the rpm of the

turbocharger is limited by bypassing a portion of the exhaust

gases around the turbine wheel of the turbocharger.

NOTE:

The wastegate turbocharger is preset at the

factory and no adjustments can be made.

6-16