TM 5-3895-383-24

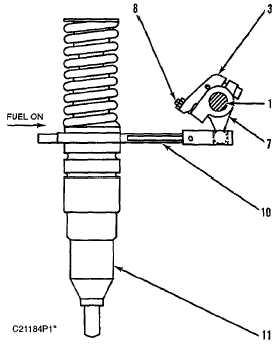

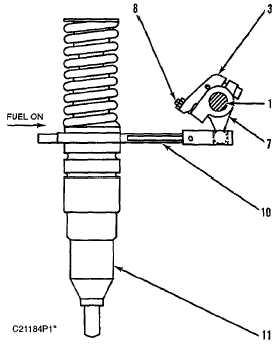

View AA From Injectors And Rack Control Linkage (Previous)

Illustration

(1) Shaft. (3) Clamp. (7) Lever assembly. (8) Synchronization

screw. (10) Rack. (11) Injector.

The rack control linkage connect the governor output to fuel

injector (11) at each cylinder. The governor output shaft is

pinned to link (4). Link (4) is connected to lever assembly (6).

When the governor demands more fuel, link (4) and lever

assembly (6) cause FUEL ON rotation of shaft (1) and clamps

(3). Each clamp then pushes lever assembly (7) as the shaft

rotates. Fuel Injector rack (10) is pulled by lever assembly (7),

allowing more fuel to be injected into the cylinder.

When the governor demands less fuel, link (4) causes shaft (1)

and clamps (3) to rotate in the FUEL OFF direction. Torsion

spring (2) then forces lever assembly (7) to also rotate

clockwise, pushing injector rack (10) toward shutoff. Torsion

spring (2), at each lever assembly (7), allows the rack control

linkage to go to shutoff, even if one injector rack is stuck open.

Power setting of the No. 1 cylinder injector is made with fuel

setting screw (5) in clamp assembly (9). As fuel setting screw

(5) is turned, shaft (1) rotates to a new position with respect to

link (4) and lever assembly (6). Adjusting screws (8) allow

synchronization of the injectors to the injector of No. 1 cylinder.

NOTICE

Do not loosen screws holding clamps (3) or clamp

assembly (9) to shaft (1). These screws are factory set to

the shaft (the screws can be identified as those with

socket heads filled with sealant). Loosening the clamps

will cause poor engine performance and may cause

damage to the engine.

Governor

The governor transfers the operator's requirements to the fuel

injector rack control linkage. The governor receives the

desired engine speed by the position of the throttle. The

governor output shaft immediately moves when the throttle is

moved. The motion of the governor output shaft then causes

the injector rack control linkage to rotate and move the injector

racks. As engine speed changes because of the rack change,

the governor adjusts the amount of fuel delivered. This causes

the engine to stabilize at the speed corresponding to the

throttle position. For further information refer to 3114, 3116 &

3126 Governor Service Manual, SENR6454.

6-13