TM 5-3895-382-24

Steering Control Unit Drive Timing

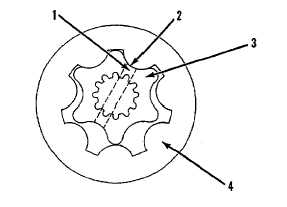

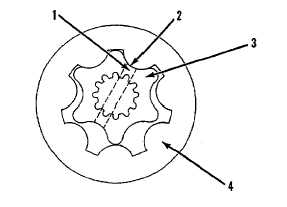

Steering Control Unit Dive Timing.

(1) Cross pin. (2) Rotor tooth used for alignment. (3) Rotor. (4)

Stator.

Cross pin (1) must align with the bottom of rotor tooth (2).

Pump Efficiency Check

For any pump test at a given rpm, the pump flow at 690 kPa

(100 psi) will be larger than the pump flow at 6900 kPa (1000

psi). The difference between the pump flow of the two

operating pressures is the flow loss.

Method for finding flow loss:

Pump flow at 100 psi .................................... 57.5 gpm (liter/min)*

Pump flow at 1000 psi .................................-52.0 gpm (liter/min)*

Flow loss ............................................................5.5 gpm (liter/min)*

Flow loss when expressed as a percent of pump flow is used

as a measure of pump performance.

Example of finding percent of flow loss:

gpm flow loss

Pump flow @ 100 psi

X 100 =

Percent of

flow loss

*5.5

or

*57.5

X 100 = 9.5%

If the percent of flow loss is more than 10%, pump

performance is not good enough.

*Numbers in examples are for illustration and are not values for

any specific pump or pump condition. See Specifications for

pump flow of a new pump at 690 kPa (100 psi) and 6900 kPa

(1000 psi).

If the test bench can be run at 6900 kPa (1000 psi) and at full

pump rpm, find the percent of flow loss using Formula I.

If the test bench cannot be run at 6900 kPa (1000 psi) and at

full pump rpm, run the pump shaft at 1000 rpm. Measure the

pump flow at 690 kPa (100 psi) and at 6900 kPa (1000 psi).

Use these values in the top par of Formula II. For the bottom

part of the formula, run the pump shaft at 2000 rpm. Measure

the pump flow at 690 kPa (100 psi).

Formula 2:

gpm @ 100 psi - gpm @ 1000 psi

gpm @ 100 psi @ 2000 rpm

X 100 =

Percent of

flow loss

System Pressure Check

Make

reference

to

WARNING

on

first

page

of

Troubleshooting.

Tools Needed

4C4892

ORFS Fittings Group

1

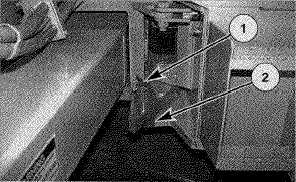

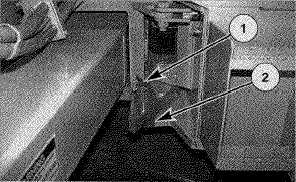

Frame Lock Pin Installed.

(1) Lock pin. (2) Yoke.

1. Apply the parking brake.

14-15