TM 5-3895-383-24

Table 1-1. Unit Preventive Maintenance Checks and Services – CONT.

Location

Item

Man-

Item to be

Not Fully Mission

No.

hour

Checked or

Capable If:

Interval

Serviced

Procedure

It's time to replace vee belts when they are...

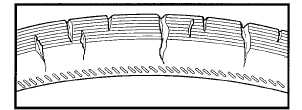

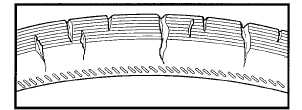

cracked or split.

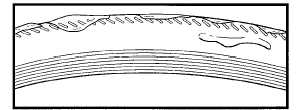

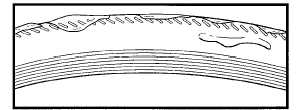

greasy.

Check for cracks or splits on bottom

Grease buildup causes belts to

or sides of belt. A cracked or split

soften, rot, and fail.

belt can fail at any time.

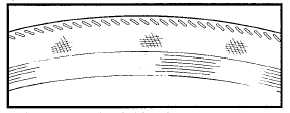

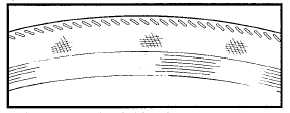

glazed.

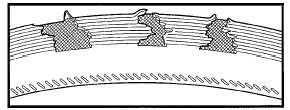

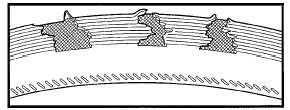

peeling.

Belts with slick, hard sides do not

When the underside of the belts peel, it

function properly. This can cause the

becomes uneven, causing rough

radiator or other components to

operation and failure.

overheat.

15

250 H

0.1

Vee Belts

Check vee belts for excessive wear and belt tightness.

Any alternator

or Q

Replace or adjust accordingly

vee belt is loose,

(Page 1-123).

missing, broken,

greasy, peeling,

glazed, cracked to

the belt fiber, has

more than one crack

(1/8 inch in depth or

50% of belt

thickness), or has

frays more than 2

inches long.

16

500 H

0.1

Blade Cutting

a. Inspect blade cutting edge for loose or missing

Cutting edge has

or S

Edge

bolts.

loose or missing

bolts.

b. Inspect cutting edge for damage such as cracks or

tears.

c. Inspect that cutting edges are not worn beyond 1/8

Edge is worn beyond

in. from blade.

1/8 in. from blade.

1-13