TM 5-3895-382-24

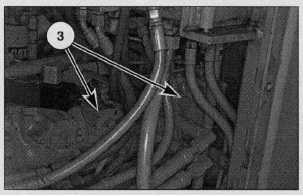

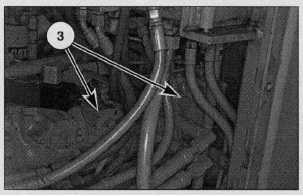

Charge oil for the propel system is supplied by the steering

system. The steering system sends filtered charge oil to

pumps (3). Flow from the pumps is controlled by the propel

control lever on the operator console. A control cable connects

the lever to the front pump. A linkage rod connects the front

pump to the rear pump. The operator uses the propel lever to

control direction and speed of the machine. The pumps supply

oil to drum and axle drive motors (4) and (5). Case drain oil

from the motors flows through thermal bypass valve (9). Oil in

the bypass valve flows either to oil cooler (13) or back to

hydraulic oil tank (10).

The speed shift control valve sends charge oil to the drive

motors to change the motor displacement for high and low

speeds. The parking brake valve controls the flow of charge oil

to the brake in the drum drive motor.

Below Operator Platform.

(3) Tandem propel pumps.

Propel pumps (3) are located under the operator platform. The

propel pumps are variable-displacement piston pumps that

provide minimum pressure to the system when the machine is

not moving.

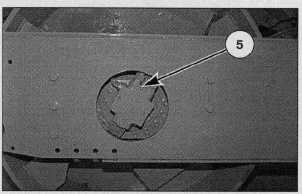

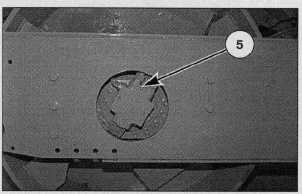

Left Side Of Drum.

(5) Drum drive motor.

Drum drive motor (5) is located on the left side of the drum.

The motor is a variable displacement, bi-directional piston type

motor. When the machine propels it receives high pressure oil

from the front section (pump closest to the flywheel) of the

tandem propel pump. It transmits the torque through a

planetary gear reduction gearbox to the drum. Isolation

mounts are used to isolate drum vibration internal gearbox and

yoke.

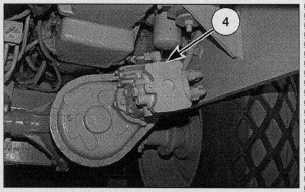

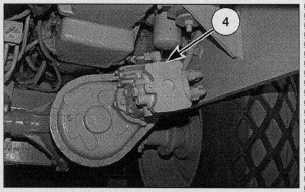

Rear Axle.

(4) Axle propel motor.

Axle propel motor (4) is located on the rear of the axle. The

motor is a variable-displacement, bi-directional and piston-type

motor. When the machine propels, the motor receives high-

pressure oil from the rear section of the tandem pump. The

motor transmits the torque through the axle assembly to the

rear wheels.

11-5