TM 5-3895-379-23

TROUBLESHOOTING PROCEDURES - CONTINUED

0006 00

Table 1. Engine Troubleshooting Procedures - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

2.

Engine Starts But Will Not Keep

Running - Continued.

WARNING

There is no clearance for personnel between frame and yoke when

roller turns. Injury or death from crushing could occur.

Steering frame must be locked before lifting, transporting or servic-

ing roller in articulation area with engine running. Failure to follow

this warning may cause injury or death from crushing.

Unlock steering frame before operation to prevent loss of steering.

Failure to follow this warning may cause injury or death.

When working on a running engine, provide shielding for exposed

rotating parts. Tools, clothing, or hands can get caught and cause

injury.

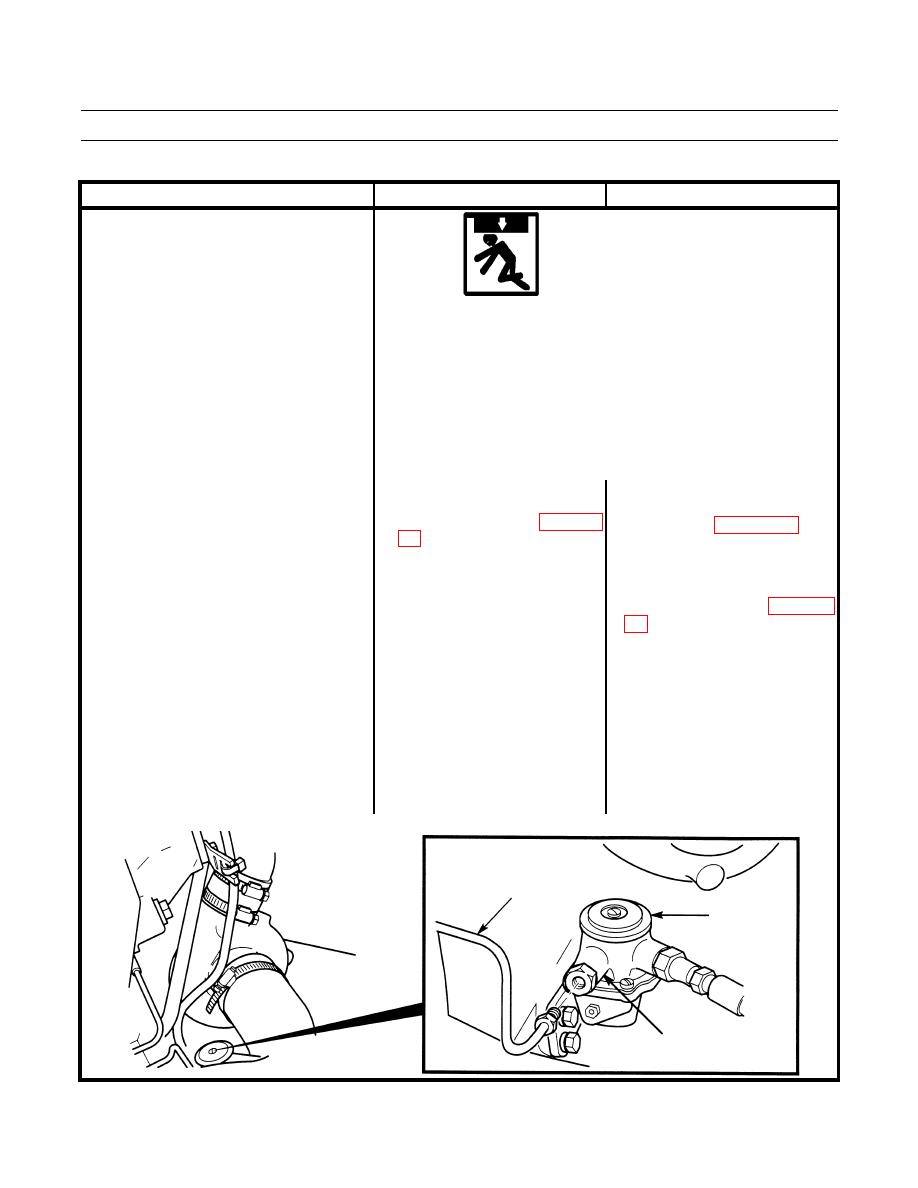

4. Check fuel lift pump pressure. 1. If fuel pump outlet pressure is

Remove fuel line from output

below 4.5 psi (30 kPa), replace

port of fuel lift pump (WP 0028

fuel lift pump (WP 0028 00).

output port of fuel lift pump. Turn 2. If time for maximum pressure

noted during cranking to drop by

on battery disconnect switch and

one half is less than 30 seconds,

lock steering frame. Have an

assistant crank engine for 10

replace fuel lift pump (WP 0028

seconds. Observe pressure gauge.

Note highest indication on

pressure gauge. Normal pressure

is 6 - 10 psi (40 - 70 kPa).

Minimum pressure is 4.5 psi (30

kPa). Turn engine start switch

OFF. Observe amount of time for

maximum pressure noted during

cranking to drop by one half.

Time should be greater than 30

seconds. Remove pressure gauge

from fuel lift pump.

FUEL

LINE

LIFT PUMP

OUTPUT PORT

401-176

0006 00-11