5.1 Water Pump

DETROIT DIESEL 53

Inspection

Wash all of the pump. parts, except the bearing and shaft assembly,

in clean fuel oil and dry them with compressed air.

NOTE: A permanently sealed and lubricated bearing is used

in the bearing and shaft assembly and should not be washed.

Wipe the bearing and shaft assembly with a clean lint-less cloth.

Examine the impeller for damage and excessive wear on the

impeller face which contacts the seal. Replace the impeller if it is

worn or damaged. Discard the bearing if it has a general feeling of

roughness, is tight or has indications of damage.

Assemble Pump

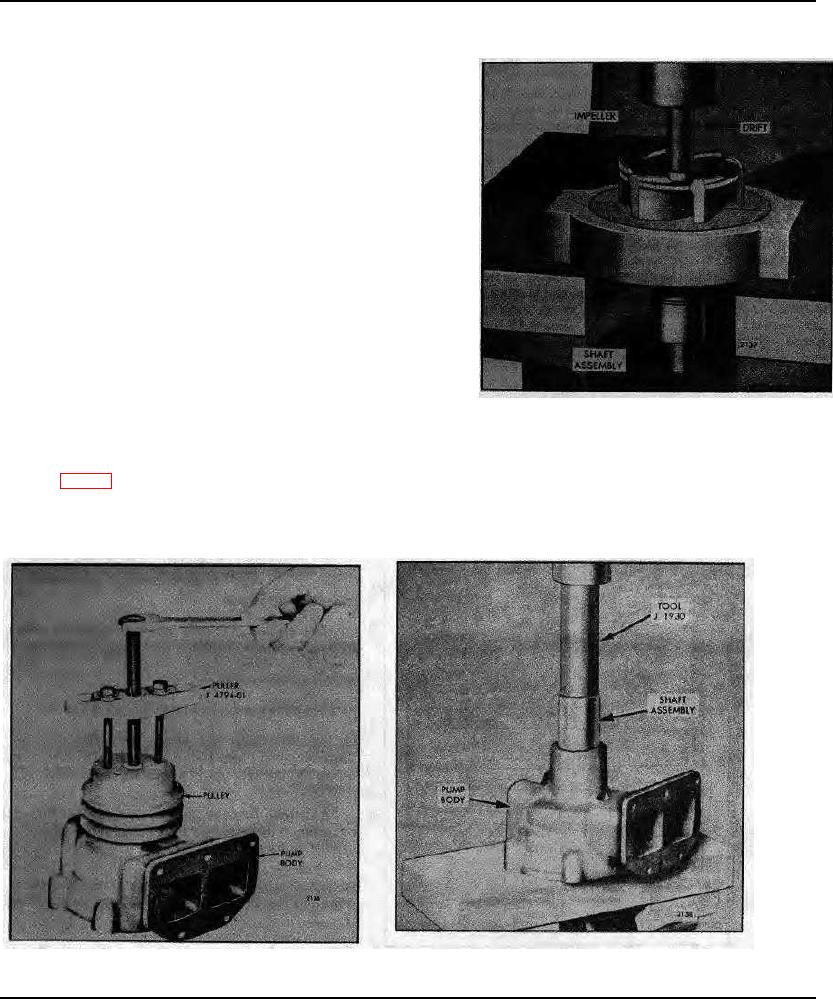

1. Use installer J 1930 to apply pressure to the outer race of the

bearing as shown in Fig. 5 and press the shaft and bearing assembly

into the pump body until the outer race of the bearing is flush with the

outer face of the body.

The bearing will be damaged if the bearing and

CAUTION:

Fig. 4 - Removing Shaft from Impeller with

shaft assembly is installed by applying pressure on the end of the shaft.

Tools J 8329 and J 358-1

2. Lightly coat the outside diameter of the new seal with sealing compound. Then, with the face of the body and the

bearing outer race supported, install the seal by applying pressure on the seal outer flange only, until the flange contacts

the body (Fig. 1). Wipe the face of the seal with a chamois to remove all dirt and metal particles.

3. Support the pulley end of the shaft on the bed of an arbor press and press the impeller on the shaft until the impeller

is flush with the large end of the body.

Fig. 3 - Removing Pulley

Fig. 5 - Pressing Shaft Assembly into Water Pump

Page 2