DETROIT DIESEL 53

FUEL Injector

2.1.1

Operation

Fuel, under pressure, enters the injector at the inlet side through a filter cap and filter (Fig. 2). From the filter, the fuel

passes through a drilled passage into the supply chamber,' that area between the plunger bushing and the spill

deflector, in addition to that area under the injector plunger within the bushing. The plunger operates up and down in the

bushing, the bore of which is open to the fuel supply in the annular chamber by two funnel-shaped ports in the plunger

bushing.

The motion of the injector rocker arm is transmitted to the plunger by the follower which bears against the follower spring

(Fig. 6). In addition to the reciprocating motion, the plunger can be rotated, during operation, around its axis by the gear

which meshes with the control rack; For metering the fuel, an upper helix and a lower helix are machined in the lower

part of the plunger. The relation of the helices to the two ports changes with the rotation of the plunger.

As the plunger moves downward, under pressure of the injector rocker arm, a portion of that fuel trapped under the

plunger is displaced into the supply chamber through the lower port until the port is closed oil' h, the lower end of the

plunger. A portion of' the fuel trapped below the plunger is then forced up through a central passage in the plunger into

the fuel metering recess and into the supply chamber through the upper port until that port is closed off by the upper helix

of the plunger. With the upper and lower ports both closed off, the remaining fuel under the plunger is subjected to

increased pressure by the continued downward movement of the plunger.

When sufficient pressure is built up, it opens the flat, non-return check valve. The fuel in the check valve cage, spring

cage, tip passages and tip fuel cavity is compressed until the pressure force acting upward on the needle valve is

sufficient to open the valve against the downward force of the valve spring. As soon as the needle valve lifts off of its

seat, the fuel is forced through the small orifices in the spray tip and atomized into the combustion chamber.

When the lower land of the plunger uncovers the lower port in the bushing, the fuel pressure below the plunger is relieved

and the valve spring closes the needle valve, ending injection. A pressure relief passage has been provided in the spring

cage to permit bleed-off of fuel leaking past the needle pilot in the tip assembly.

A check valve, directly below the bushing, prevents leakage from the combustion chamber into the fuel

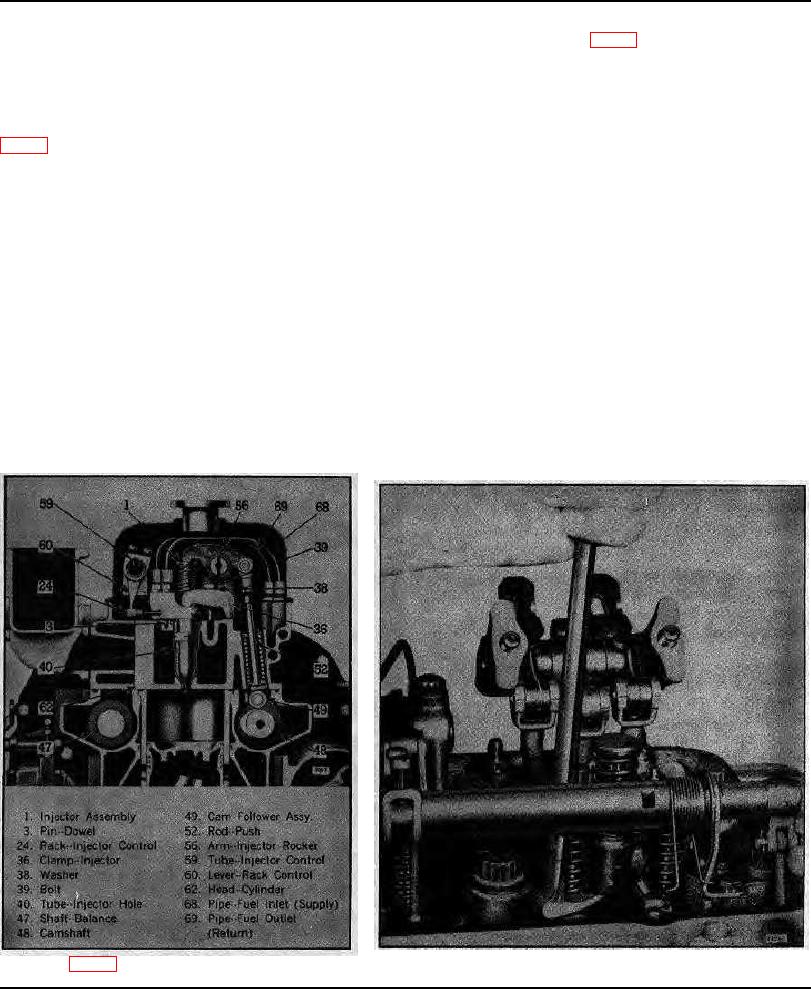

Fig. 6 Fuel Injector Mounting

Fig. 7 Removing Injector from Cylinder Head

March, 1973

SEC. 2.1.1

Page 3